Humidity-Enhanced Ceramic Doubles Fuel Cell Performance: A Game-Changing Study

A recent study conducted at the Institute of Science, Tokyo, revealed that water vapor can significantly boost the performance of fuel cells when introduced to humidity-enhanced ceramic materials. This groundbreaking research has the potential to revolutionize the fuel cell industry by nearly doubling the efficiency of these energy conversion devices.

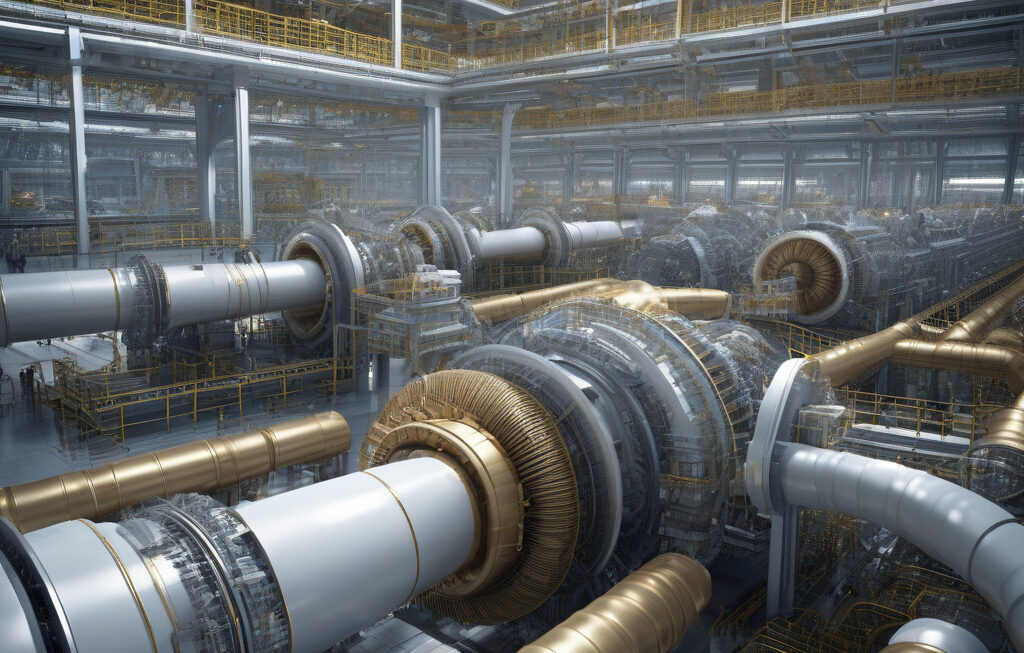

Fuel cells are clean and efficient power sources that have gained traction in various industries, including automotive, aerospace, and stationary power generation. However, their widespread adoption has been hindered by limitations in performance and cost. One key challenge has been the sluggish reaction kinetics of the oxygen reduction reaction (ORR) at the cathode, which is crucial for fuel cell operation.

The Tokyo study focused on addressing this challenge by exploring the impact of humidity on ceramic materials commonly used in solid oxide fuel cells (SOFCs). The researchers found that by exposing the ceramic electrolyte to water vapor, they could enhance the ORR kinetics and overall cell performance. This humidity-enhanced ceramic exhibited a nearly 100% increase in power density compared to conventional dry-operating conditions.

The mechanism behind this remarkable improvement lies in the ability of water molecules to adsorb onto the ceramic surface and facilitate the ORR process. The presence of water vapor creates an environment rich in oxygen vacancies, which serve as active sites for the ORR. As a result, the fuel cell operates more efficiently, producing higher power outputs with the same amount of fuel input.

The implications of this study are profound for the future of fuel cell technology. By leveraging the power of humidity-enhanced ceramics, manufacturers can develop fuel cells that are not only more efficient but also cost-effective. The use of inexpensive ceramic materials and ambient air as a source of water vapor eliminates the need for complex humidification systems, simplifying fuel cell design and operation.

Furthermore, the scalability of this approach makes it suitable for a wide range of fuel cell applications, from portable electronics to grid-scale energy storage. Imagine electric vehicles with extended driving ranges, drones that can fly longer missions, and decentralized power plants that operate with minimal environmental impact – all made possible by humidity-enhanced ceramic technology.

As researchers continue to explore the potential of this innovation, collaborations between academia and industry will be crucial to bring humidity-enhanced ceramic fuel cells from the lab to the market. By investing in further research and development, stakeholders can accelerate the commercialization of this technology and unlock its full potential for a sustainable energy future.

In conclusion, the study conducted at the Institute of Science, Tokyo, has paved the way for a new era in fuel cell technology. By harnessing the power of water vapor and ceramic materials, researchers have unlocked a pathway to significantly improve the performance of fuel cells. This advancement not only enhances energy efficiency but also opens doors to a wide range of applications that can benefit from clean and reliable power generation.

fuel cell, humidity-enhanced ceramic, energy efficiency, sustainable technology, power generation