Dog crate-sized robot factory learns to assemble electronics by watching humans

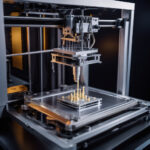

A San Francisco-based company has developed a robotic system that is installed in a small space no larger than a dog crate, yet its capabilities are far beyond its size. This innovative robot factory is designed to learn and replicate the intricate process of assembling electronics by observing and mimicking human workers.

The company behind this groundbreaking technology, which prefers to remain discreet about its operations, has perfected a system that combines artificial intelligence and advanced robotics to revolutionize the manufacturing industry. By leveraging machine learning algorithms, the robot factory is capable of analyzing the movements and techniques used by human operators, allowing it to autonomously assemble electronic components with precision and efficiency.

One of the key advantages of this dog crate-sized robot factory is its adaptability. Traditional assembly line robots are often programmed for a specific task and lack the flexibility to adjust to new products or variations in the manufacturing process. In contrast, this innovative system can quickly learn and adapt to different assembly requirements by simply observing human workers in action. This level of adaptability not only streamlines the production process but also reduces the need for reprogramming or retooling when introducing new products.

The implications of this technology are vast. With the ability to rapidly learn and replicate complex tasks, the robot factory offers manufacturers a cost-effective solution to labor-intensive assembly processes. By automating the assembly of electronics, companies can increase production efficiency, reduce errors, and ultimately lower manufacturing costs.

Furthermore, the integration of artificial intelligence and robotics in this compact system represents a significant step forward in the ongoing evolution of smart manufacturing. As Industry 4.0 continues to shape the future of manufacturing, innovative solutions like the dog crate-sized robot factory are at the forefront of this transformative wave. By combining the power of AI with advanced robotics, companies can unlock new levels of productivity and competitiveness in an increasingly digital world.

While the full extent of the capabilities of this robot factory remains confidential, industry experts speculate that its potential applications could extend beyond electronics assembly. From automotive components to consumer electronics, the adaptability and scalability of this technology open doors to a wide range of industries seeking to enhance their manufacturing processes.

In conclusion, the development of a dog crate-sized robot factory that learns to assemble electronics by watching humans marks a significant milestone in the realm of advanced manufacturing. By harnessing the power of artificial intelligence and robotics in a compact and adaptable system, companies have the opportunity to revolutionize their production lines and stay ahead in an ever-evolving market landscape.

innovations, robotics, manufacturing, artificial intelligence, efficiency