Airbus Revolutionizes Aircraft Cooling Systems with 3D-Printed Heat Exchangers

In a groundbreaking move towards sustainability and innovation, Airbus is set to transform the aviation industry with the development of 3D-printed heat exchangers for their future hydrogen-electric jets. Collaborating with Conflux Technology, a pioneering company specializing in advanced heat transfer solutions, Airbus aims to lead the way in eco-friendly aircraft design.

The aviation sector is under increasing pressure to reduce its environmental impact and carbon footprint. In response to this challenge, Airbus has unveiled its ZEROe initiative, which focuses on developing hydrogen-powered aircraft to achieve zero-emission flights. As part of this ambitious project, Airbus has turned to Conflux Technology to create cutting-edge heat exchangers that will play a crucial role in cooling the next generation of aircraft.

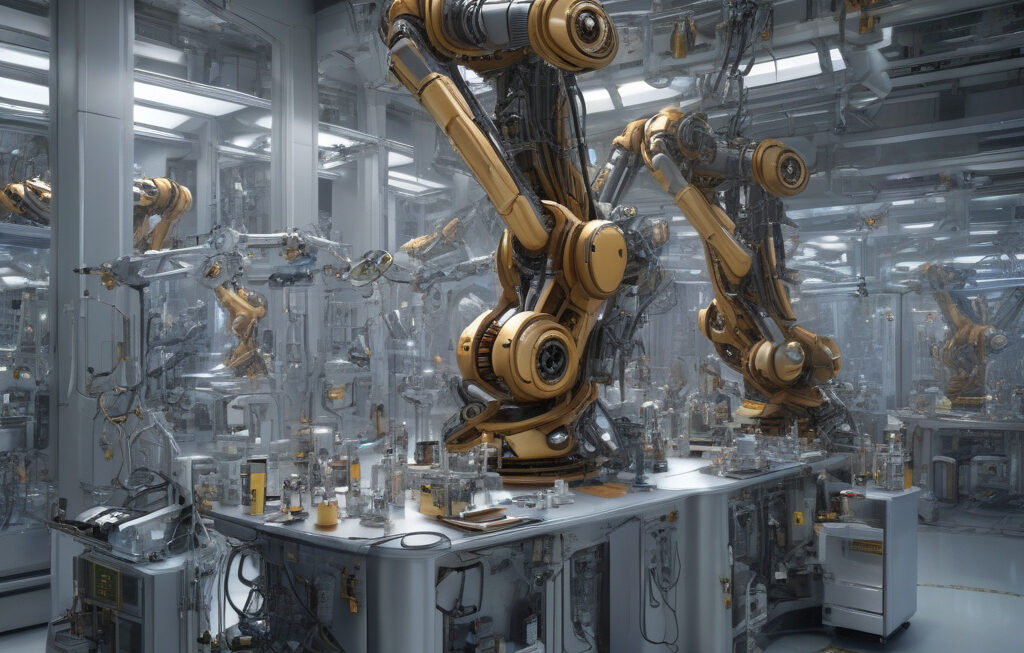

Heat exchangers are essential components in aircraft cooling systems, responsible for regulating temperature and ensuring optimal performance. By leveraging 3D printing technology, Conflux Technology can produce heat exchangers with intricate designs that were previously impossible to achieve using traditional manufacturing methods. This innovative approach not only enhances the efficiency of the heat exchangers but also reduces weight and material waste, contributing to overall fuel savings and environmental sustainability.

One of the key advantages of 3D-printed heat exchangers is the ability to customize their shapes and structures to maximize heat transfer efficiency. This level of design flexibility allows engineers to optimize the performance of the heat exchangers, resulting in more effective cooling of critical aircraft systems. In addition, 3D printing enables rapid prototyping and iteration, speeding up the development process and ultimately leading to faster implementation of new technologies.

Furthermore, the use of 3D printing in manufacturing heat exchangers offers significant cost savings over traditional methods. By eliminating the need for complex tooling and reducing production waste, Airbus can achieve greater efficiency in the manufacturing process and ultimately lower the overall production costs. This cost-effectiveness is crucial for the widespread adoption of innovative technologies in the aviation industry and paves the way for more sustainable practices in aircraft design and production.

As Airbus continues to push the boundaries of aircraft innovation, the collaboration with Conflux Technology represents a significant step towards a more sustainable and environmentally friendly future for aviation. By investing in cutting-edge technologies like 3D-printed heat exchangers, Airbus demonstrates its commitment to driving positive change in the industry and setting new standards for aircraft design and performance.

In conclusion, the development of 3D-printed heat exchangers for Airbus’ hydrogen-electric jets marks a milestone in the evolution of aircraft cooling systems. With the expertise of Conflux Technology and the vision of Airbus’ ZEROe initiative, the aviation industry is poised to embrace a new era of sustainability and innovation. By harnessing the power of 3D printing, Airbus sets a new standard for eco-friendly aircraft design, inspiring other manufacturers to follow suit in the quest for greener skies.

#Airbus, #ConfluxTechnology, #3DPrinting, #AircraftInnovation, #SustainableAviation