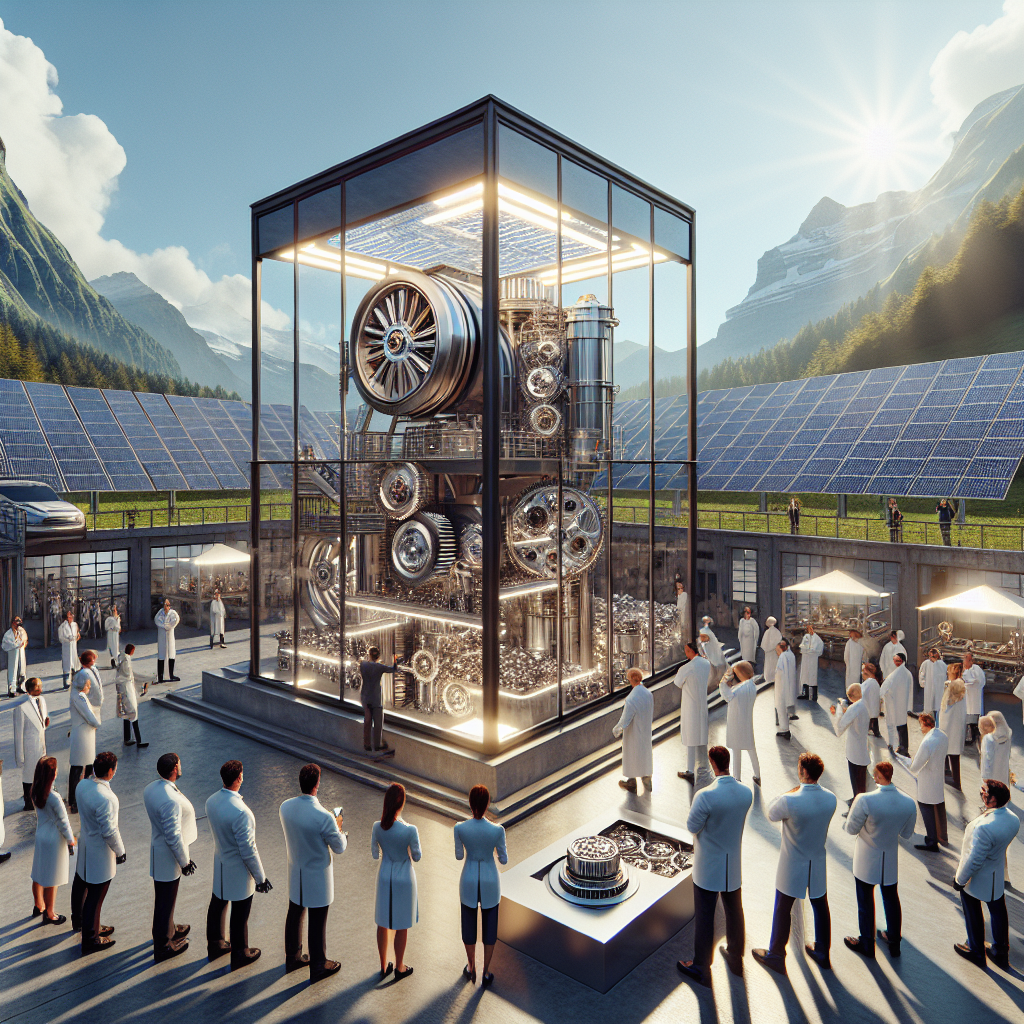

World’s First Solar Furnaces Unveiled to Recycle Luxury Swiss Watch Scrap Steel

A Swiss company has recently launched the world’s first two solar furnaces that will reportedly revolutionize the recycling process for luxury Swiss watch scrap steel. This groundbreaking technology is set to not only transform the way in which precious metals are extracted from discarded timepieces but also significantly reduce the environmental impact of the watchmaking industry.

The innovative solar furnaces, developed by SolarTech Solutions, harness the power of the sun to melt down and purify scrap steel from luxury watches. By utilizing solar energy as a clean and renewable heat source, these furnaces eliminate the need for traditional fossil fuels, making the recycling process much more sustainable and eco-friendly.

One of the key advantages of these solar furnaces is their ability to operate with zero carbon emissions, making them a truly environmentally conscious solution for the watchmaking industry. This aligns with the growing trend of sustainability in luxury goods production, as consumers are becoming increasingly aware of the environmental footprint of the products they purchase.

In addition to their eco-friendly benefits, the solar furnaces also offer a more cost-effective and efficient method of recycling scrap steel. By using solar power, companies can significantly reduce their energy costs associated with the recycling process, making it a win-win situation for both the environment and the bottom line.

Furthermore, the purity and quality of the recycled steel produced by these solar furnaces are of the highest standard, ensuring that luxury watch manufacturers can create new timepieces with the same level of excellence and craftsmanship as those made from freshly mined materials. This not only helps to conserve precious resources but also adds a unique selling point for brands looking to appeal to environmentally conscious consumers.

The introduction of the world’s first solar furnaces for recycling luxury Swiss watch scrap steel marks a significant milestone in the watchmaking industry’s journey towards a more sustainable future. As other sectors begin to adopt similar clean technologies and innovative solutions, we can expect to see a positive shift towards a circular economy that prioritizes resource efficiency and environmental stewardship.

In conclusion, the unveiling of these solar furnaces represents a major step forward in the quest for sustainable practices within the luxury watch industry. By harnessing the power of the sun to recycle scrap steel, companies can not only reduce their environmental impact but also benefit from cost savings and enhanced product quality. As the demand for eco-conscious products continues to rise, initiatives like these are essential for driving positive change and shaping a more sustainable world for future generations.

luxury watches, Swiss watchmaking, solar technology, sustainable recycling, environmental innovation