From Plastic Waste to 3D Printing Threads: Germany’s Innovative Solution to Environmental Challenges

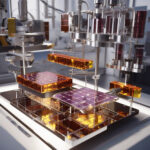

The Fraunhofer Institute is transforming millions of metric tons of household plastic waste into high-quality 3D printing threads, marking a significant step towards sustainability and innovation in Germany. This groundbreaking initiative not only addresses the pressing issue of plastic pollution but also showcases the potential for repurposing waste materials into valuable resources.

With approximately 1.8 million tons of plastic waste generated in Germany each year, finding effective ways to manage and recycle this waste is crucial for environmental conservation. The traditional methods of disposing of plastic waste, such as landfill or incineration, pose serious environmental risks and contribute to the depletion of natural resources. By harnessing the power of technology and innovation, the Fraunhofer Institute is leading the charge in turning this environmental challenge into an opportunity for growth and development.

Through advanced recycling processes, the Institute is able to convert plastic waste from households into high-quality 3D printing threads. These threads can then be used in a wide range of applications, from manufacturing to construction, opening up new possibilities for sustainable production methods. By utilizing recycled materials in 3D printing, manufacturers can reduce their reliance on virgin plastics and decrease their carbon footprint, contributing to a more circular and eco-friendly economy.

The benefits of this innovative approach are manifold. Not only does it help reduce the amount of plastic waste that ends up in landfills or oceans, but it also promotes resource efficiency and supports the transition towards a more sustainable society. By demonstrating the viability of using recycled plastics in 3D printing, the Fraunhofer Institute is setting a positive example for other industries and countries to follow.

Moreover, the production of 3D printing threads from recycled plastic waste is a testament to the power of collaboration and interdisciplinary research. By bringing together experts from various fields, including materials science, engineering, and environmental studies, the Institute has been able to develop a cutting-edge solution that addresses both environmental and technological challenges. This multidisciplinary approach underscores the importance of cooperation and knowledge sharing in driving innovation and positive change.

As we look towards the future, initiatives like the one spearheaded by the Fraunhofer Institute serve as a reminder of the untapped potential that lies within our waste streams. By reimagining waste as a valuable resource and investing in sustainable technologies, we can create a more resilient and environmentally conscious society. The transformation of plastic waste into 3D printing threads is just the beginning of what is possible when we combine creativity, ingenuity, and a commitment to sustainability.

In conclusion, Germany’s innovative approach to repurposing plastic waste into 3D printing threads represents a significant milestone in the journey towards a circular economy and a greener future. By harnessing the power of technology, research, and collaboration, the Fraunhofer Institute is paving the way for a more sustainable and environmentally friendly world.

plasticwaste, 3Dprinting, sustainability, innovation, environmentalconservation