US Scientists Test Heat-Treated 3D-Printed Steels for Next-Gen Nuclear Reactors

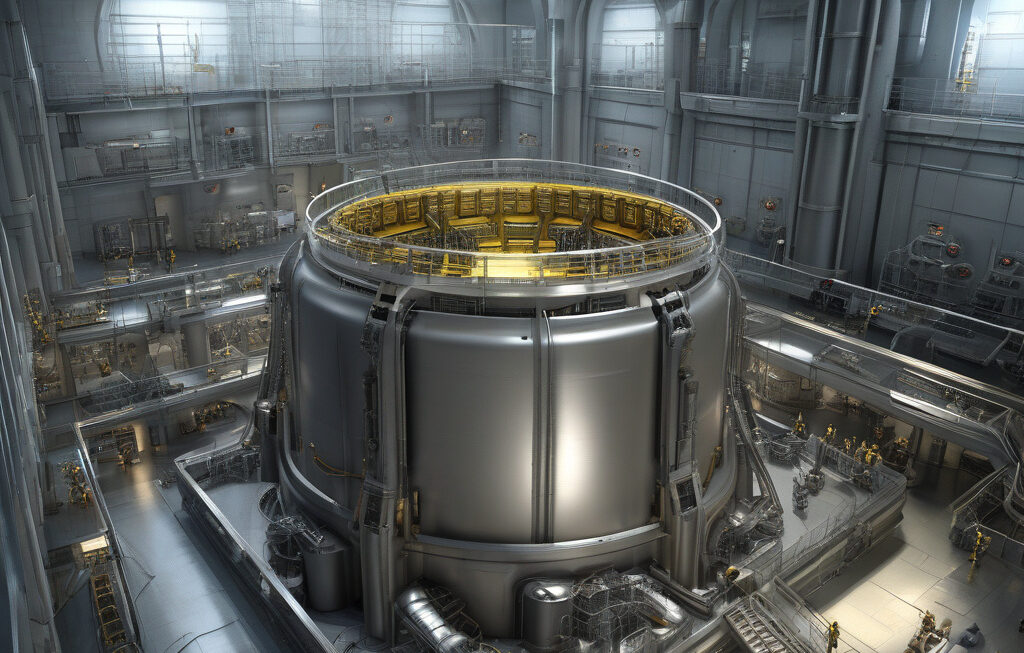

Steel is one of the most essential components for the nuclear energy industry, among others. Its strength, durability, and heat resistance make it a crucial material for various applications, especially in the construction of nuclear reactors. In recent developments, US scientists have been exploring the use of heat-treated 3D-printed steels for next-generation nuclear reactors, aiming to enhance efficiency and safety in nuclear power plants.

The traditional manufacturing methods for steel components in nuclear reactors involve casting or forging, which can be time-consuming and labor-intensive. With the advancements in 3D printing technology, scientists have found a more efficient and cost-effective way to produce complex steel parts with enhanced properties. By utilizing additive manufacturing techniques, such as selective laser melting or electron beam melting, researchers can create intricate designs that were previously impossible to achieve with conventional methods.

One of the main advantages of 3D-printed steels is the ability to tailor their microstructure through heat treatment processes. By carefully controlling the heating and cooling cycles, scientists can manipulate the material’s properties, such as hardness, toughness, and corrosion resistance. This level of customization enables researchers to develop steels that are specifically optimized for use in nuclear reactors, where extreme conditions of temperature, pressure, and radiation exposure are present.

In a recent study conducted by a team of US scientists, heat-treated 3D-printed steels were subjected to rigorous testing to evaluate their performance under simulated reactor conditions. The results showed that these advanced steels exhibited superior mechanical properties and resistance to irradiation damage compared to conventional steels. This promising outcome paves the way for the use of 3D-printed steels in next-generation nuclear reactors, where safety and reliability are of utmost importance.

Furthermore, the adoption of 3D-printed steels in the nuclear energy industry can lead to significant advancements in reactor design and operation. The ability to fabricate complex geometries with high precision allows for the optimization of structural components, leading to improved efficiency and reduced maintenance costs. Moreover, the use of additive manufacturing can shorten lead times for production and repair, ensuring minimal downtime for nuclear power plants.

As the demand for clean and sustainable energy sources continues to grow, the development of advanced materials like heat-treated 3D-printed steels plays a critical role in shaping the future of nuclear power. By harnessing the power of additive manufacturing and heat treatment technologies, scientists are pushing the boundaries of innovation in the quest for safer and more efficient nuclear reactors.

In conclusion, the ongoing research and testing of heat-treated 3D-printed steels by US scientists represent a significant step forward in the advancement of next-generation nuclear reactors. The combination of additive manufacturing and tailored heat treatment processes offers unprecedented opportunities to enhance the performance and reliability of steel components in nuclear power plants. With further developments and collaborations in this field, we can expect to see a new era of innovation in the nuclear energy industry.

steel, nuclear reactors, 3D printing, heat treatment, US scientists