Scientists Develop New Timed Laser Technique to Pause Ultra-Fast Silicon Melting

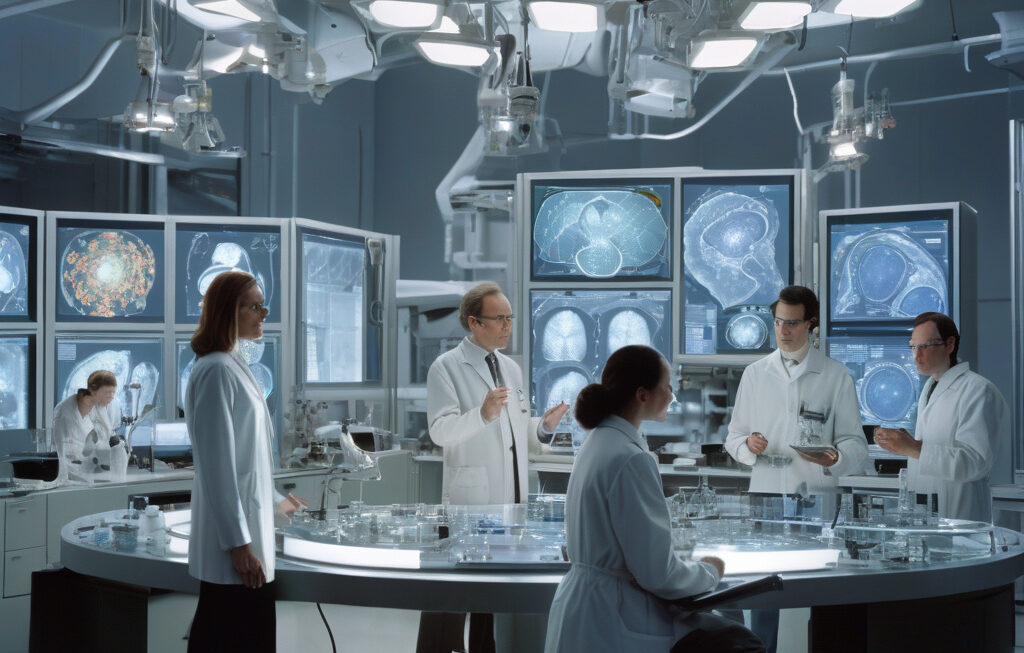

A team of researchers from University of California and the University of Kassel in Germany have made a groundbreaking discovery in the field of laser technology. By developing a new timed laser technique, they have successfully paused ultra-fast silicon melting, opening up a world of possibilities for the future of materials science and industrial applications.

The conventional wisdom in laser technology has been that once a material begins to melt under the intense heat of a laser, the process is irreversible and uncontrollable. However, this team of scientists has defied that notion by precisely timing the delivery of their laser pulses to halt silicon melting at a specific point in time. This level of precision has never been achieved before and marks a significant advancement in the field.

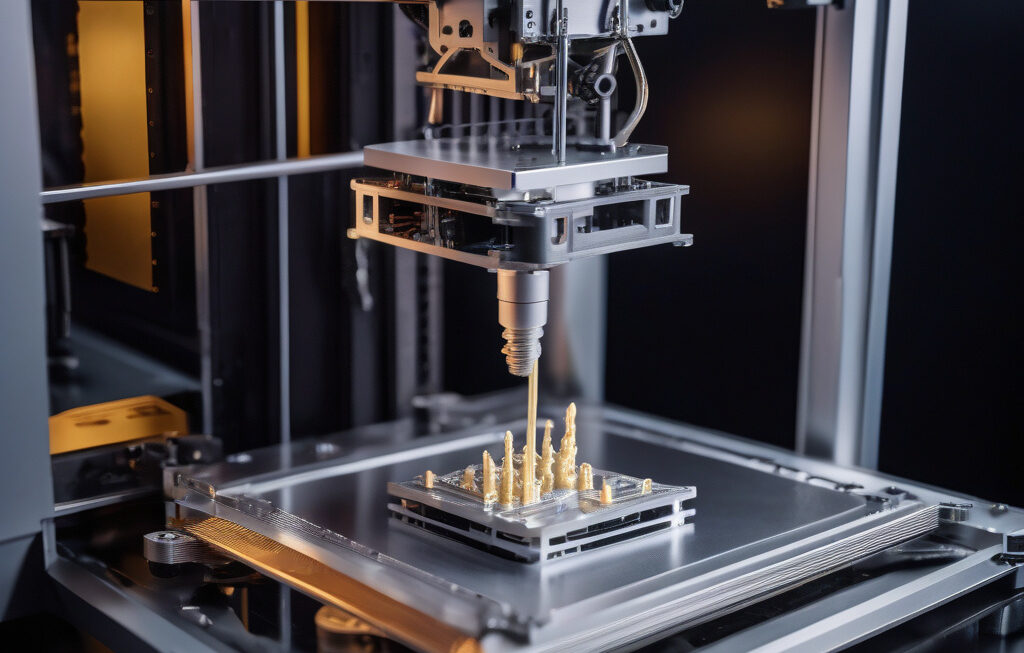

So, how exactly does this new timed laser technique work? The researchers utilized ultra-short laser pulses on silicon samples to induce rapid melting. By carefully adjusting the timing of subsequent laser pulses, they were able to interfere with the melting process at the precise moment it began, effectively “freezing” the molten silicon in its tracks. This level of control over the melting process has far-reaching implications for numerous industries, from semiconductor manufacturing to energy production.

One of the key advantages of this new technique is its potential impact on the development of faster and more efficient electronic devices. Silicon is a foundational material in the production of semiconductors, and the ability to control its melting process with such precision could lead to the creation of smaller, more powerful microchips. This, in turn, could revolutionize the capabilities of various technologies, from smartphones to supercomputers.

Moreover, the applications of this timed laser technique extend beyond the realm of electronics. In the field of materials science, the ability to pause ultra-fast melting opens up new avenues for studying the properties of molten materials in unprecedented detail. Researchers can now observe and analyze the behavior of molten silicon with a level of precision that was previously unattainable, leading to a deeper understanding of its thermal and optical properties.

From a practical standpoint, this innovation also has the potential to optimize industrial processes that rely on laser technology. By offering a method to precisely control the melting of materials, manufacturers may be able to improve the efficiency and quality of processes such as laser cutting, welding, and 3D printing. This could result in cost savings, reduced waste, and enhanced productivity across a wide range of industries.

In conclusion, the development of this new timed laser technique represents a significant leap forward in the field of laser technology and materials science. By successfully pausing ultra-fast silicon melting, the team of researchers from the University of California and the University of Kassel has demonstrated the power of precision and control in laser applications. The implications of this discovery are far-reaching, with the potential to reshape industries and drive innovation for years to come.

research, laser technology, silicon melting, materials science, industrial applications