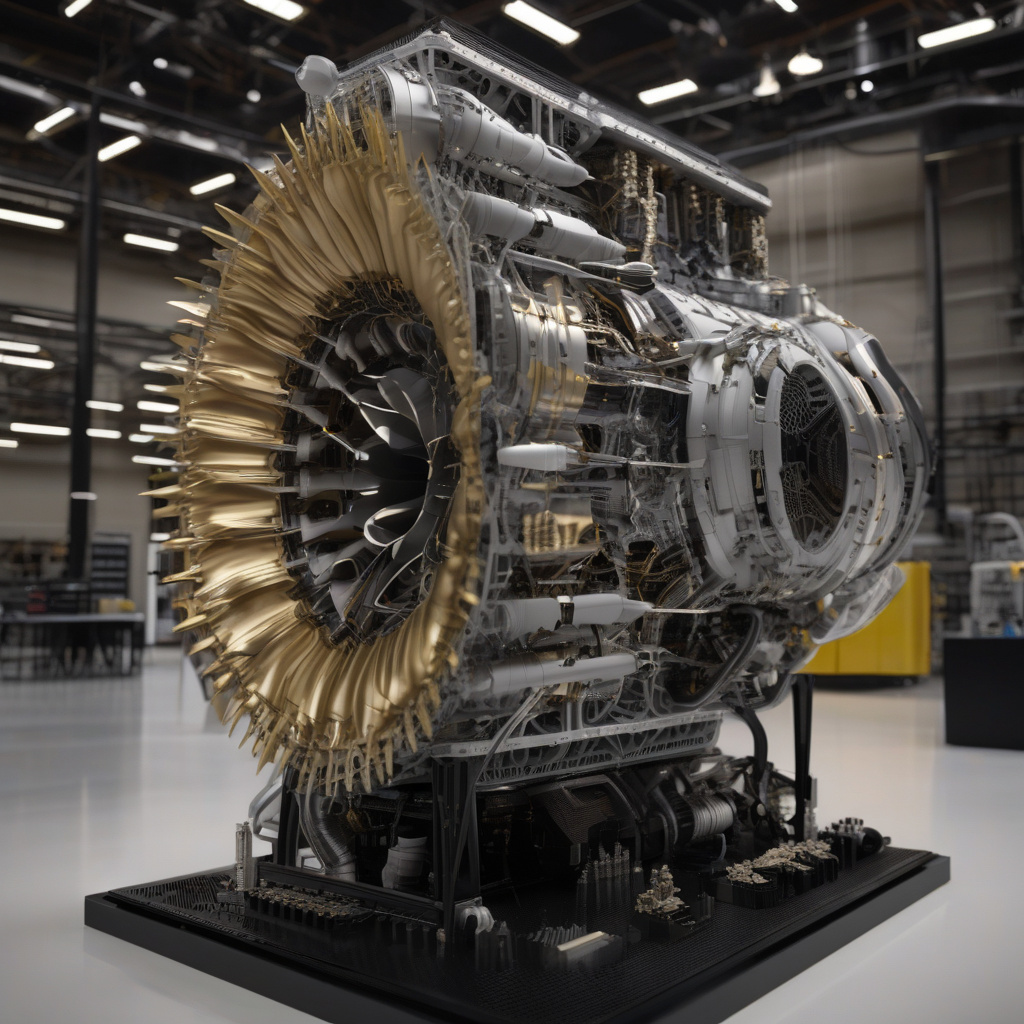

A Texas-Based Company Achieves a Milestone: 3D-Printed Hybrid Rocket Engine for US Army Reaches 18,000 Feet Vertical Ascent

A Texas-based company has completed the inaugural flight test of a 3D-printed hybrid rocket engine, marking a significant advancement in propulsion technology for the US Army. The successful test flight demonstrated the engine’s capability to propel a rocket to an impressive vertical ascent of 18,000 feet, showcasing the potential of additive manufacturing in revolutionizing aerospace engineering.

The company behind this groundbreaking achievement has been at the forefront of innovation in the field of propulsion systems, leveraging cutting-edge technologies to push the boundaries of what is possible. By harnessing the power of 3D printing, they have been able to overcome traditional manufacturing constraints and unlock new opportunities for developing high-performance rocket engines.

One of the key advantages of 3D printing in the aerospace industry is the ability to design and produce complex geometries that are not feasible with conventional manufacturing methods. This flexibility allows engineers to optimize the engine’s performance and efficiency, leading to improved thrust, fuel consumption, and overall reliability.

Moreover, additive manufacturing enables rapid prototyping and iteration, significantly reducing the time and cost involved in developing new engine designs. This agility is crucial in the fast-paced world of rocket technology, where innovation is key to gaining a competitive edge and staying ahead of the curve.

In addition to its technical advantages, 3D printing also offers sustainability benefits by minimizing material waste and energy consumption compared to traditional manufacturing processes. This aligns with the growing emphasis on environmental responsibility in the aerospace sector, where reducing the carbon footprint of operations is a top priority.

Furthermore, the successful test flight of the 3D-printed hybrid rocket engine highlights the importance of collaboration between the private sector and government agencies like the US Army. By working together, industry players and military stakeholders can drive innovation, enhance national security, and accelerate the deployment of cutting-edge technologies for defense applications.

Looking ahead, the possibilities for 3D-printed rocket engines are virtually limitless, with potential applications ranging from small satellite launches to hypersonic aircraft propulsion. As additive manufacturing continues to advance and mature, we can expect to see even more groundbreaking achievements in the field of aerospace engineering.

In conclusion, the recent milestone achieved by the Texas-based company in developing a 3D-printed hybrid rocket engine for the US Army represents a significant leap forward in propulsion technology. By harnessing the power of additive manufacturing, engineers have unlocked new capabilities and set the stage for a new era of innovation in aerospace engineering.

#3Dprinting, #RocketTechnology, #AerospaceEngineering, #Innovation, #USArmy