Revolutionizing EV Development: Luxury Automaker Recycles High-Voltage Batteries for Sustainable Innovation

A luxurious German automobile manufacturer is recycling high-voltage batteries to recover valuable raw materials after their first life in electric vehicles (EVs). This innovative approach not only showcases a commitment to sustainability but also paves the way for transforming EV development.

As the demand for EVs continues to rise, the need for high-voltage batteries has become increasingly significant. These batteries play a crucial role in powering electric vehicles, providing the necessary energy for long drives and efficient performance. However, one of the challenges associated with these batteries is their disposal at the end of their lifespan. Improper disposal can lead to environmental pollution and the wastage of valuable resources.

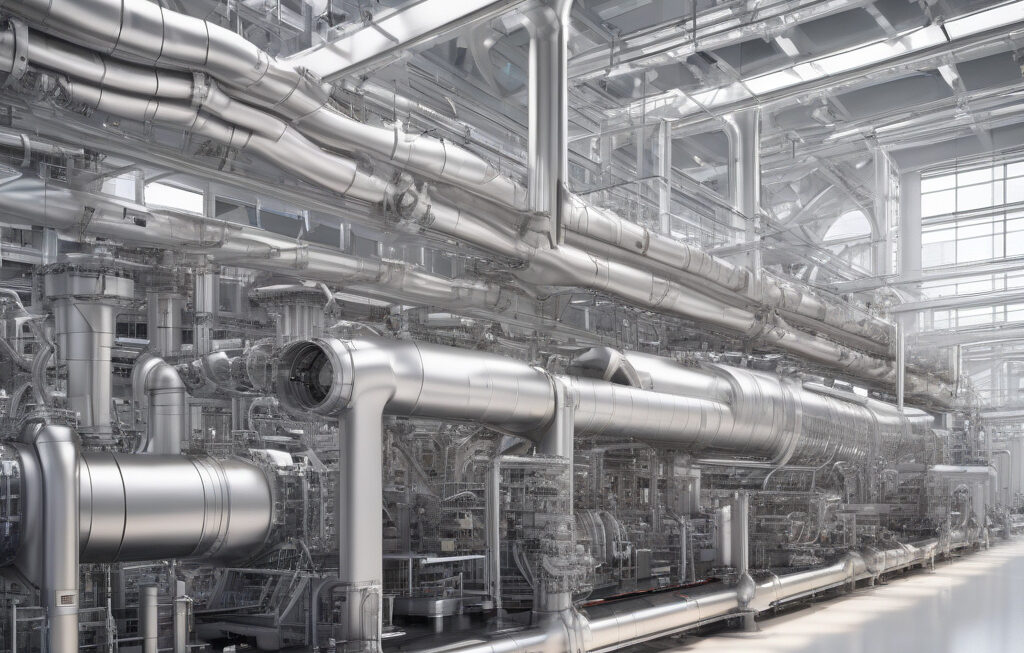

To address this issue, the German automaker has implemented a cutting-edge recycling program that focuses on recovering raw materials from high-voltage batteries. By disassembling and processing these batteries, the manufacturer can extract materials such as lithium, cobalt, and nickel, which can then be used to produce new batteries. This closed-loop approach not only reduces the environmental impact of battery disposal but also minimizes the reliance on newly mined resources.

The benefits of this recycling initiative extend beyond environmental stewardship. By reusing valuable materials from old batteries, the automaker can reduce production costs for new batteries, making EVs more cost-effective for consumers. Additionally, by securing a local and stable supply of raw materials, the manufacturer can ensure a more sustainable and resilient EV manufacturing process.

Furthermore, this recycling program aligns with the growing trend towards circular economy practices in the automotive industry. Instead of following a linear model of production and disposal, where resources are used once and then discarded, the automaker is embracing a circular approach that promotes resource efficiency and waste reduction. This shift towards a more sustainable business model not only benefits the environment but also enhances the brand’s reputation as a leader in innovation and corporate responsibility.

The impact of recycling high-voltage batteries goes beyond the automotive sector. By demonstrating the feasibility and benefits of battery recycling, the German automaker is setting an example for other industries that rely on battery technology, such as renewable energy storage and consumer electronics. This ripple effect can lead to widespread adoption of recycling practices, further contributing to the transition towards a more sustainable and circular economy.

In conclusion, the decision of the luxurious German automobile manufacturer to recycle high-voltage batteries marks a significant step towards sustainable innovation in EV development. By recovering valuable raw materials from old batteries, the automaker is not only reducing waste and production costs but also setting a precedent for circular economy practices in the automotive industry and beyond. As the demand for EVs continues to grow, initiatives like this will play a vital role in driving the transition towards a more sustainable and environmentally friendly future.

electricvehicles, sustainability, innovation, circular economy, automotiveindustry