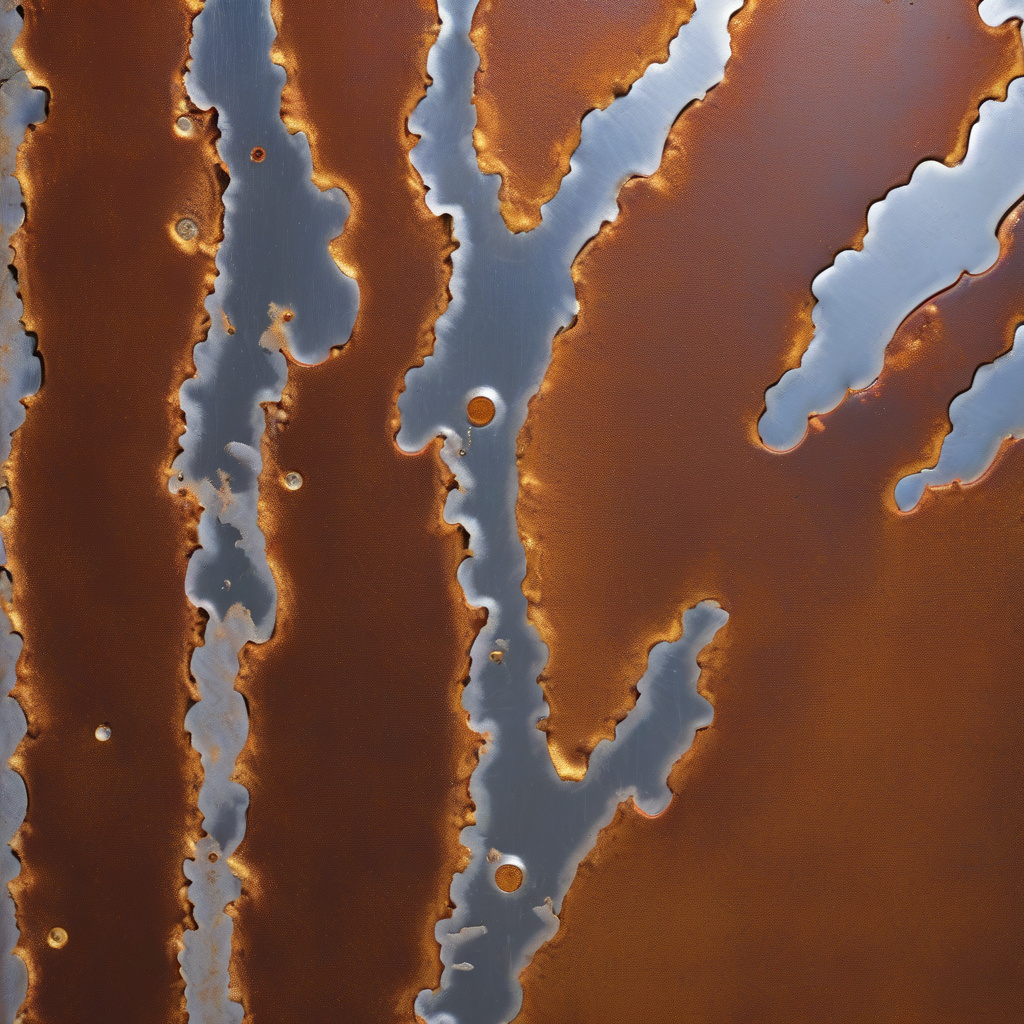

New Coating Forms Strong, Lasting Rust Barrier for Iron with 99.6% Efficiency

A new dual-layer coating has been developed that offers 99.6% protection against iron corrosion. Iron, a fundamental element in various industries, is prone to rust when exposed to moisture and oxygen. This innovative coating not only prevents rust formation but also ensures a long-lasting barrier, providing a significant advancement in the protection of iron-based structures and components.

Iron corrosion, commonly known as rust, is a pervasive issue that leads to structural weakening and deterioration of iron materials over time. Industries such as construction, automotive, and manufacturing rely heavily on iron for its strength and durability, making the prevention of rust a top priority. Traditional methods of rust prevention, such as painting and galvanization, have limitations in terms of longevity and effectiveness.

The new dual-layer coating addresses these limitations by offering unparalleled protection with an efficiency rate of 99.6%. The first layer of the coating acts as a primer, bonding tightly to the iron surface and creating a strong foundation for the second layer. This second layer serves as the main protective barrier, shielding the iron from environmental factors that trigger corrosion.

What sets this coating apart is its durability and longevity. Unlike traditional coatings that may degrade over time, the dual-layer design ensures that the protection remains intact for extended periods. This means that structures and components treated with this coating will have a significantly prolonged lifespan, reducing the need for frequent maintenance and replacement.

In addition to its exceptional protective properties, the new coating is also environmentally friendly. By preventing rust and corrosion, it helps prolong the life of iron-based products, reducing the overall environmental impact of manufacturing and construction processes. This aligns with the growing global focus on sustainable practices and eco-conscious solutions.

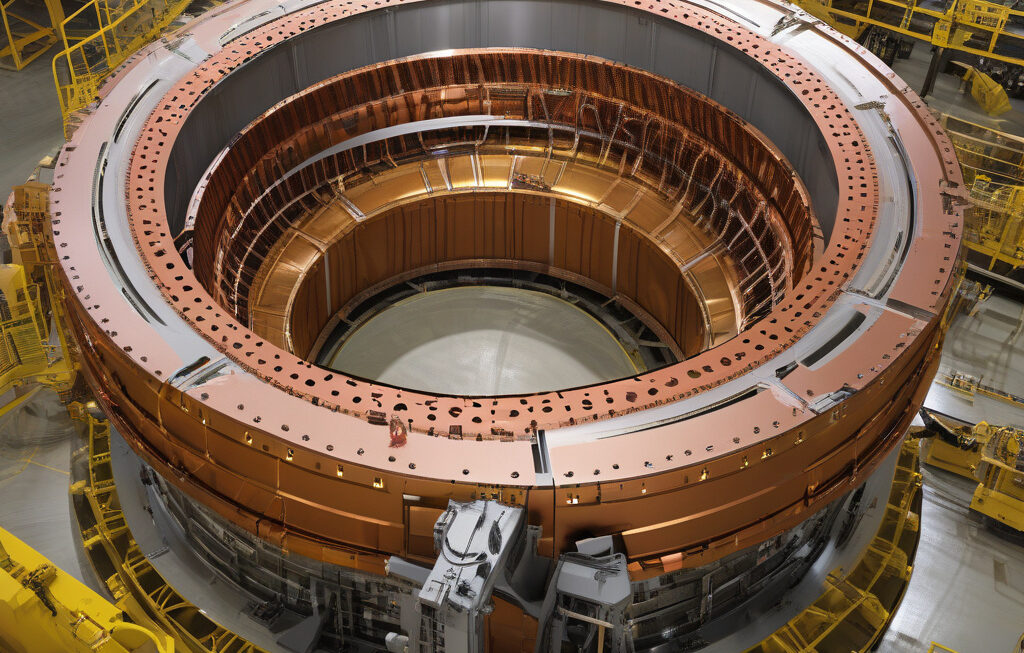

The implications of this breakthrough in coating technology are far-reaching. Industries can now enhance the durability and reliability of their iron-based assets, leading to cost savings and improved safety standards. Infrastructure exposed to harsh environmental conditions, such as bridges, pipelines, and marine structures, can benefit greatly from this advanced rust protection solution.

Furthermore, the versatility of the dual-layer coating opens up possibilities for innovation in design and construction. Engineers and architects can explore new avenues in utilizing iron materials without the constraints imposed by conventional rust prevention methods. This freedom to create robust and aesthetically pleasing structures will drive creativity and advancement in various fields.

In conclusion, the development of a dual-layer coating that offers 99.6% protection against iron corrosion marks a significant milestone in the industry. With its exceptional efficiency, durability, and environmental benefits, this coating sets a new standard for rust prevention in iron-based applications. As industries adopt this innovative solution, we can expect to see a paradigm shift in the way we approach the protection and maintenance of iron structures.

corrosion protection, iron coating, innovative technology, sustainability, industrial advancements