Electrical Pulses Boost Copper’s Efficiency in Turning CO2 into Ethylene, Ethanol Fuels

Scientists have observed a remarkable growth in copper’s ability to convert carbon dioxide (CO2) into valuable products such as ethylene and ethanol. This groundbreaking discovery showcases the potential of electrical pulses in enhancing the efficiency of copper catalysts for carbon dioxide conversion, offering a promising solution to address environmental challenges while producing sustainable fuels.

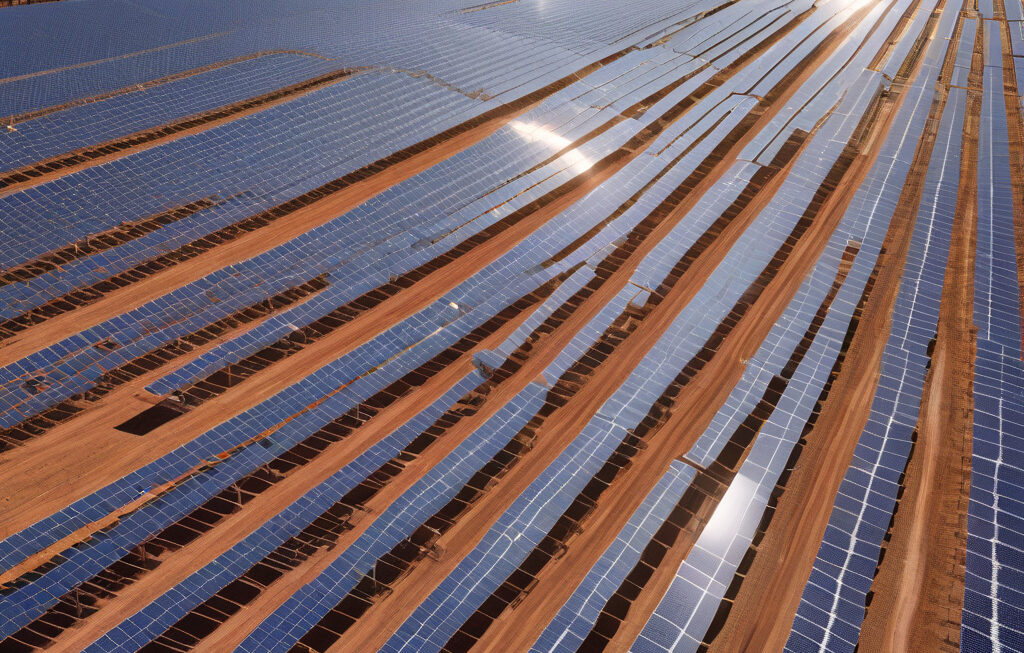

Carbon dioxide, a greenhouse gas linked to climate change, is a major byproduct of industrial processes and transportation. Finding innovative ways to reduce CO2 emissions and transform them into useful chemicals is crucial for a more sustainable future. Copper has long been recognized for its catalytic properties in converting CO2 into valuable products, but its efficiency has been limited by factors such as high energy requirements and low selectivity.

In a recent study published in the journal Science, researchers detailed how applying electrical pulses to copper catalysts can significantly improve their performance in converting CO2 into ethylene and ethanol. By subjecting the copper surface to periodic high-energy pulses, the scientists were able to enhance the catalyst’s selectivity towards the desired products while reducing energy consumption.

The key to this advancement lies in the dynamic restructuring of the copper surface under the influence of electrical pulses. These pulses trigger a series of electrochemical reactions that promote the formation of specific intermediates crucial for the conversion of CO2 into ethylene and ethanol. As a result, the efficiency of the process is greatly increased, leading to higher yields of the desired products.

Furthermore, the use of electrical pulses allows for precise control over the catalytic process, enabling researchers to fine-tune reaction conditions and optimize product selectivity. This level of control is essential for commercial applications, where maximizing the production of ethylene and ethanol while minimizing unwanted byproducts is paramount.

The implications of this research extend beyond the laboratory, offering a practical and scalable approach to CO2 conversion. By harnessing the power of electrical pulses to enhance copper catalysts, industries can potentially reduce their carbon footprint while generating valuable chemicals for various applications. Ethylene, for instance, is a key building block in the production of plastics, while ethanol serves as a renewable fuel source.

As the global demand for sustainable energy and chemicals continues to rise, innovations like the use of electrical pulses in catalysis play a crucial role in driving the transition towards a greener economy. By leveraging the unique properties of copper and the precision of electrochemistry, researchers are paving the way for a more efficient and environmentally friendly approach to CO2 utilization.

In conclusion, the integration of electrical pulses into copper catalysis represents a significant advancement in the field of CO2 conversion. By boosting the efficiency and selectivity of copper catalysts, this technology holds immense potential for transforming greenhouse gases into valuable fuels and chemicals, contributing to a more sustainable future for generations to come.

copper, CO2 conversion, ethylene, ethanol fuels, sustainable energy