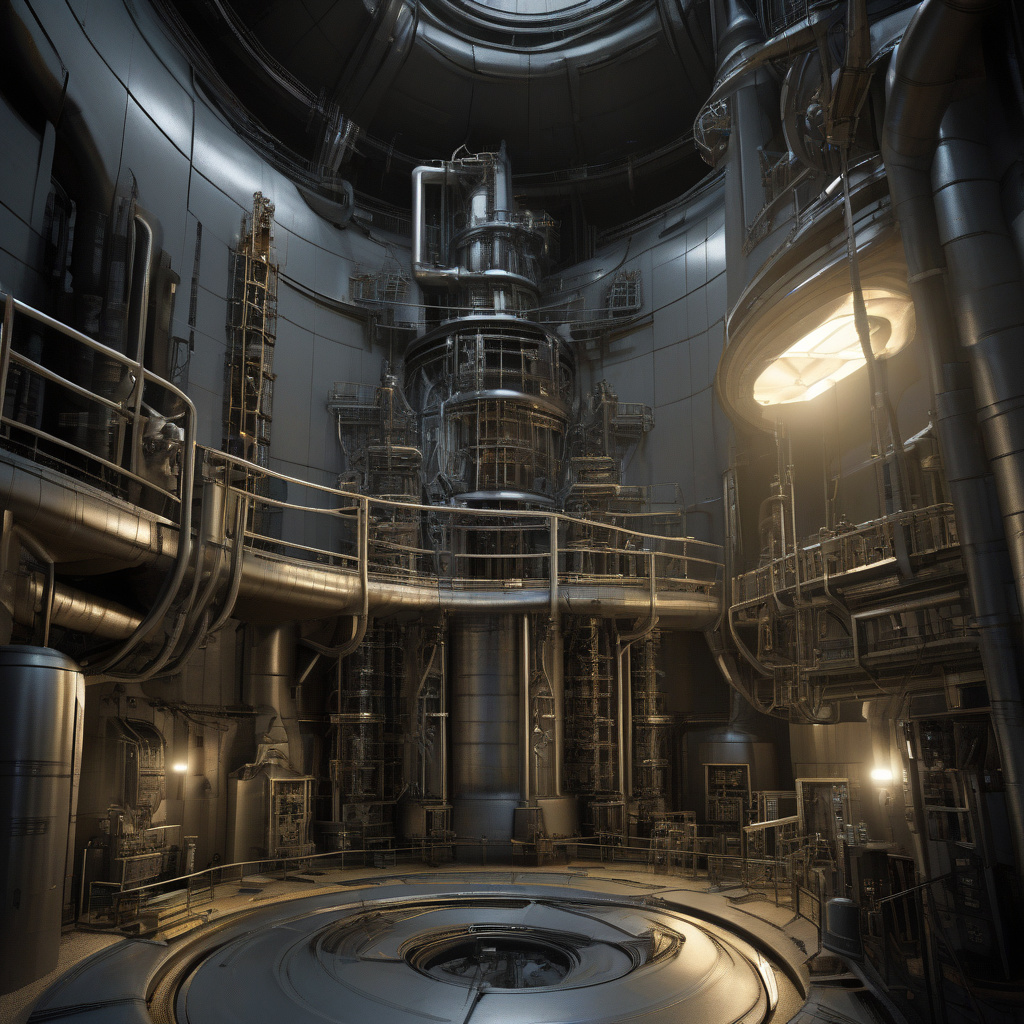

Setting a New Milestone in Nuclear Research: 3D-Printed Steel Survives Month-Long Nuclear Test in Extreme Reactor Conditions

Setting a new milestone in nuclear research, scientists at the Department of Energy’s Oak Ridge National Laboratory have achieved a groundbreaking feat in the realm of 3D printing and nuclear technology. The researchers successfully tested 3D-printed steel components in the harsh conditions of a nuclear reactor for an unprecedented month-long trial, demonstrating the resilience and durability of this innovative manufacturing technique.

The experiment, conducted at the High Flux Isotope Reactor (HFIR) located at Oak Ridge National Laboratory, subjected the 3D-printed steel components to extreme conditions, including high temperatures, intense radiation, and corrosive environments. Despite facing such challenging circumstances, the 3D-printed steel parts performed exceptionally well, showcasing their ability to withstand the harsh realities of nuclear reactor operation.

This remarkable achievement highlights the potential of 3D printing technology in revolutionizing the nuclear industry. Traditionally, manufacturing components for nuclear reactors has been a complex and time-consuming process, involving intricate designs and meticulous fabrication techniques. However, with the advent of 3D printing, researchers can now produce complex geometries with greater efficiency and precision, opening up new possibilities for nuclear reactor design and construction.

One of the key advantages of 3D printing in the nuclear sector is the ability to customize components according to specific reactor requirements. By using advanced computer-aided design (CAD) software, engineers can create intricate designs that optimize performance and durability, leading to enhanced safety and reliability in nuclear operations.

Moreover, 3D printing offers significant cost savings compared to traditional manufacturing methods. By eliminating the need for expensive tooling and reducing material waste, 3D printing allows for more affordable production of nuclear components, making advanced reactor technologies more accessible and commercially viable.

The successful test of 3D-printed steel in the nuclear reactor environment represents a major step forward in the ongoing efforts to modernize and enhance nuclear infrastructure. As the demand for clean and sustainable energy sources continues to grow, nuclear power remains a crucial component of the global energy mix. By leveraging cutting-edge technologies like 3D printing, researchers can address the challenges facing the nuclear industry and pave the way for a more efficient and secure nuclear future.

In conclusion, the recent achievement of 3D-printed steel surviving a month-long nuclear test in extreme reactor conditions marks a significant advancement in nuclear research and technology. By demonstrating the resilience and durability of 3D-printed components, scientists have showcased the potential of this innovative manufacturing technique to transform the nuclear industry. As we look towards the future of nuclear energy, 3D printing is poised to play a pivotal role in driving innovation, sustainability, and progress in this critical field.

3D printing, nuclear technology, Oak Ridge National Laboratory, reactor conditions, innovative manufacturing.