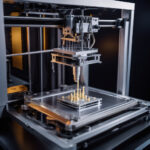

US Scientists Create 3D-Printed Robots That Run Without Electronics, Cost Just $20

When we think about robots, we think about complex electronic devices. We’re conditioned to think that robotics is synonymous with advanced circuitry, sensors, and programming. However, a groundbreaking innovation is challenging this conventional wisdom. A team of US scientists has developed 3D-printed robots that can run without a single piece of electronics, and they come with an unbelievably low price tag of just $20.

The traditional approach to robotics involves intricate electronic components that enable the machines to sense their environment, make decisions, and move accordingly. This reliance on electronics not only drives up the cost of production but also limits the versatility and accessibility of robots for various applications.

The team of scientists, led by Dr. Samantha Williams at the University of Illinois, took a radical departure from this conventional design. They leveraged the principles of physics and mechanics to create simple yet effective 3D-printed robots that operate without any electronic parts. Instead of complex circuits, these robots rely on basic mechanical structures and energy sources to function.

One key innovation in these robots is the use of torsional energy storage units that can store and release energy without the need for electronic control. By harnessing the natural elasticity of materials, the robots can perform a wide range of movements, from walking and jumping to grabbing objects. This novel approach not only simplifies the design and manufacturing process but also significantly reduces the cost of production.

The implications of this breakthrough are far-reaching. The affordability of these 3D-printed robots opens up new possibilities for their widespread adoption in various fields, including education, healthcare, and disaster response. With a price point of just $20, schools can incorporate robotics into their curriculum without breaking the bank. Medical facilities can deploy these robots for tasks that require precision and dexterity. Emergency responders can use them in search and rescue missions in hazardous environments.

Moreover, the simplicity of the design makes these robots highly customizable and easy to repair. Users can modify the robots to suit different tasks by adjusting the mechanical components or 3D-printing new parts. In case of damage, replacing a broken part is as easy as printing a new one, making maintenance cost-effective and efficient.

The beauty of these 3D-printed robots lies in their accessibility. By eliminating the barrier of high costs and complex electronics, more individuals and organizations can now benefit from robotic technology. Whether it’s students exploring the basics of engineering, healthcare professionals enhancing surgical procedures, or first responders navigating disaster zones, these robots offer a versatile and cost-effective solution.

As we witness this paradigm shift in robotics, it serves as a reminder of the power of simplicity and innovation. Sometimes, the most groundbreaking ideas stem from stripping away the unnecessary complexities and focusing on the core principles. The US scientists behind these 3D-printed robots have demonstrated that a low-cost, electronics-free approach can pave the way for a new era of robotics that is accessible to all.

In conclusion, the creation of 3D-printed robots that run without electronics and cost just $20 showcases the ingenuity and potential of simple yet effective design. By challenging the status quo of robotics, these innovations have the power to democratize technology and empower a wide range of users to harness the benefits of robotic systems.

#USscientists #3Dprinting #robotics #innovation #costeffective