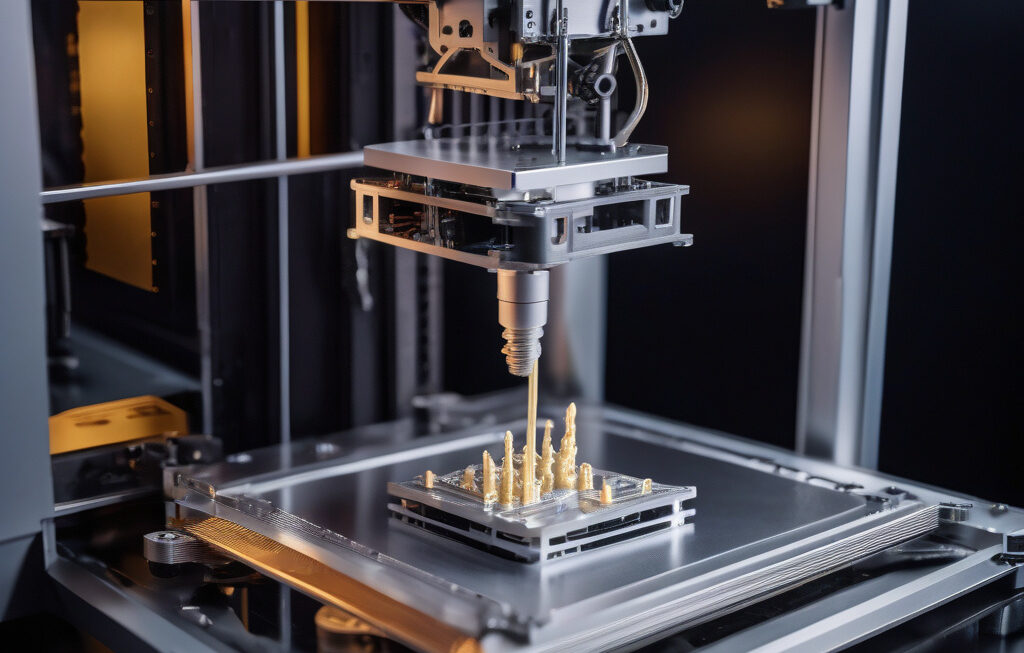

US Scientists Transform Recycled Scrap Metal into High-Performance 3D-Printed Rocket Parts

In a groundbreaking development, scientists in the US have been awarded $6.3 million to convert scrap metal into high-performance 3D-printed rocket parts. This innovative approach not only tackles the challenge of recycling metal waste but also demonstrates the endless possibilities of sustainable manufacturing in the aerospace industry.

The project, spearheaded by a team of researchers at a leading technology institute, aims to revolutionize the way rocket components are produced. By harnessing the power of 3D printing technology and utilizing recycled materials, the scientists are paving the way for a more eco-friendly and cost-effective method of manufacturing high-performance aerospace parts.

Traditionally, rocket parts are manufactured using new metal alloys, which can be costly and resource-intensive. By repurposing scrap metal, such as aluminum and steel, the researchers are not only reducing the environmental impact of aerospace manufacturing but also proving that sustainability and innovation can go hand in hand.

One of the key advantages of using recycled scrap metal in 3D printing is the ability to create complex geometries and customized designs that are not feasible with traditional manufacturing methods. This flexibility allows for the production of lightweight yet durable rocket parts that can withstand the extreme conditions of space travel.

Moreover, by leveraging the inherent properties of different metal alloys, the scientists can tailor the composition of the 3D-printed parts to enhance their performance and functionality. This level of customization opens up new possibilities for optimizing rocket design and pushing the boundaries of aerospace technology.

The implications of this research extend beyond the aerospace industry, offering a blueprint for sustainable manufacturing practices across various sectors. By demonstrating the viability of recycled materials in high-performance applications, the scientists are challenging conventional notions of production and waste management.

Furthermore, the integration of 3D printing technology into the manufacturing process highlights the importance of innovation in driving sustainable solutions. As advancements in additive manufacturing continue to accelerate, the potential for transforming recycled materials into high-value products becomes increasingly achievable.

In conclusion, the endeavor to convert recycled scrap metal into high-performance 3D-printed rocket parts represents a significant milestone in sustainable manufacturing and aerospace engineering. By harnessing the combined power of recycling, 3D printing, and material science, the scientists are shaping a future where environmental consciousness and technological advancement converge seamlessly.

#RecycledMaterials, #3DPrintingTechnology, #AerospaceInnovation, #SustainableManufacturing, #RocketTechnology