Stronger, 30% Cheaper Next-Gen 3D-Printed Titanium Alloy Revolutionizes Aerospace Industry

Engineers at Royal Melbourne Institute of Technology (RMIT) have developed a new type of 3D-printed titanium alloy that is set to revolutionize the aerospace industry. This innovative material is not only stronger than traditional titanium alloys but also comes at a significantly lower cost, making it a game-changer for aerospace manufacturers around the world.

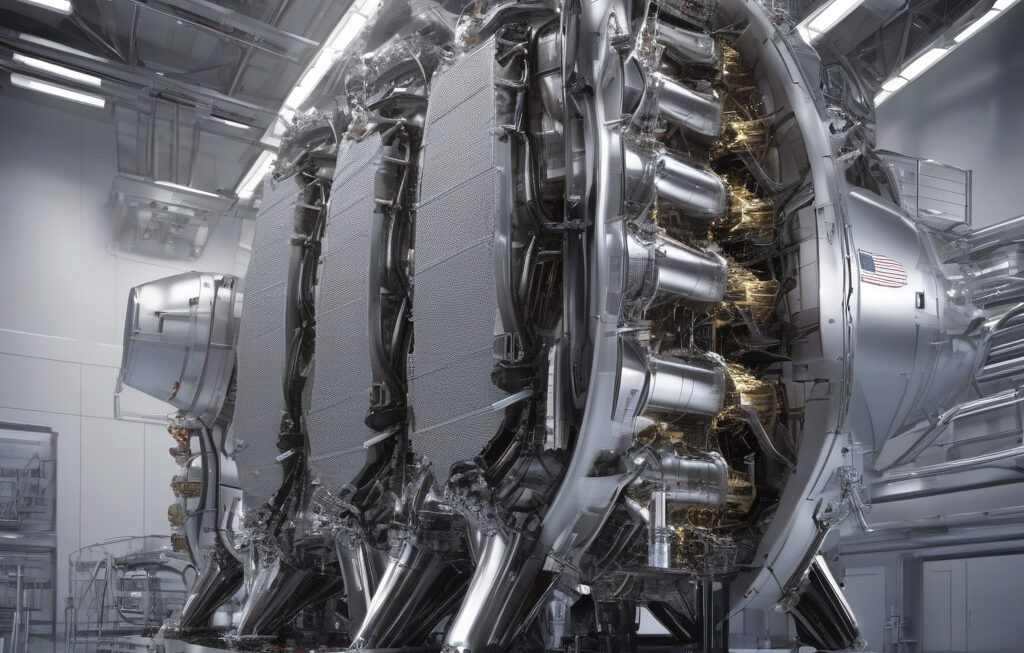

The aerospace industry has always been at the forefront of innovation, constantly pushing the boundaries of what is possible. One of the key challenges in this industry has been finding materials that are both lightweight and incredibly strong. Titanium has long been a go-to material for aerospace applications due to its high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. However, traditional manufacturing methods for titanium components can be costly and time-consuming.

With the development of this next-generation 3D-printed titanium alloy, engineers at RMIT have found a way to overcome these challenges. By utilizing advanced 3D printing techniques, they have been able to create a material that is not only stronger than existing titanium alloys but also 30% cheaper to produce. This breakthrough has the potential to significantly reduce manufacturing costs for aerospace companies, allowing them to produce lighter, more durable components for aircraft and spacecraft.

One of the key advantages of 3D printing is the ability to create complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This means that engineers can design components that are optimized for strength and performance, leading to more efficient and reliable aerospace systems. By leveraging the power of 3D printing, the new titanium alloy developed at RMIT opens up a world of possibilities for the aerospace industry.

In addition to its strength and cost-saving benefits, the next-generation 3D-printed titanium alloy also offers improved sustainability. Traditional manufacturing processes for titanium alloys can be wasteful, generating significant amounts of scrap material. 3D printing, on the other hand, is an additive manufacturing process that builds up components layer by layer, minimizing waste and reducing the environmental impact of production. This makes the new titanium alloy not only a technological advancement but also a more sustainable choice for aerospace manufacturers.

As the aerospace industry continues to evolve, materials like the next-generation 3D-printed titanium alloy developed at RMIT will play a critical role in shaping the future of flight. By providing a stronger, more cost-effective, and environmentally friendly alternative to traditional titanium alloys, this innovative material is set to drive advancements in aircraft design, performance, and efficiency. With its potential to revolutionize the way aerospace components are manufactured, the new titanium alloy is poised to take the industry to new heights.

In conclusion, the development of a stronger, 30% cheaper next-generation 3D-printed titanium alloy by engineers at RMIT represents a major breakthrough for the aerospace industry. By combining the strength and durability of titanium with the cost-saving benefits of 3D printing, this innovative material has the potential to transform the way aircraft and spacecraft are designed and manufactured. As aerospace companies around the world begin to adopt this new titanium alloy, we can expect to see lighter, more efficient, and more sustainable aerospace systems taking flight.

#aerospace #3Dprinting #titaniumalloy #RMIT #innovation