New 3D Printing Method Creates Ultra-Strong Materials Resistant to 20 Times More Pressure

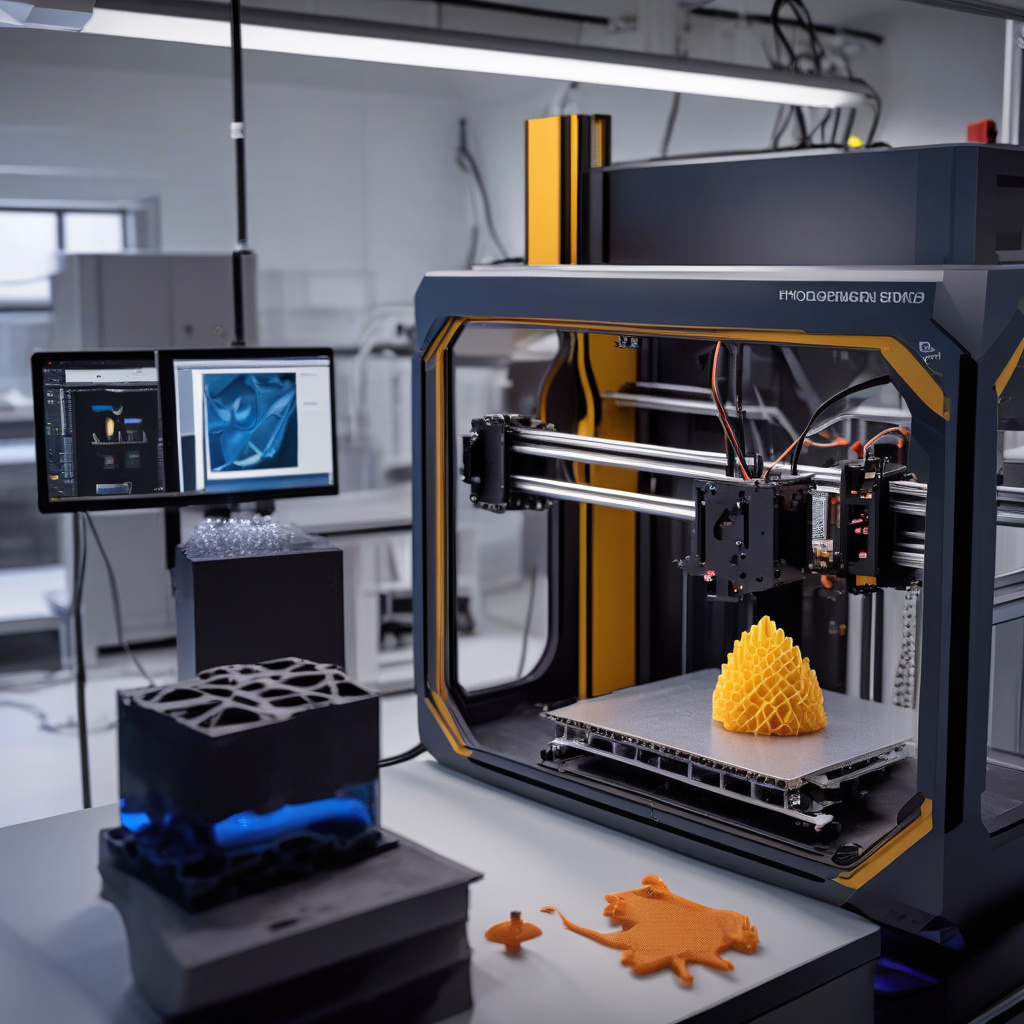

Researchers have developed a new 3D printing method that offers intricate constructions for next-generation energy, aerospace, and automotive applications. This groundbreaking technology has the potential to revolutionize the way we manufacture high-performance materials, as it enables the production of components that can withstand unprecedented levels of pressure and stress.

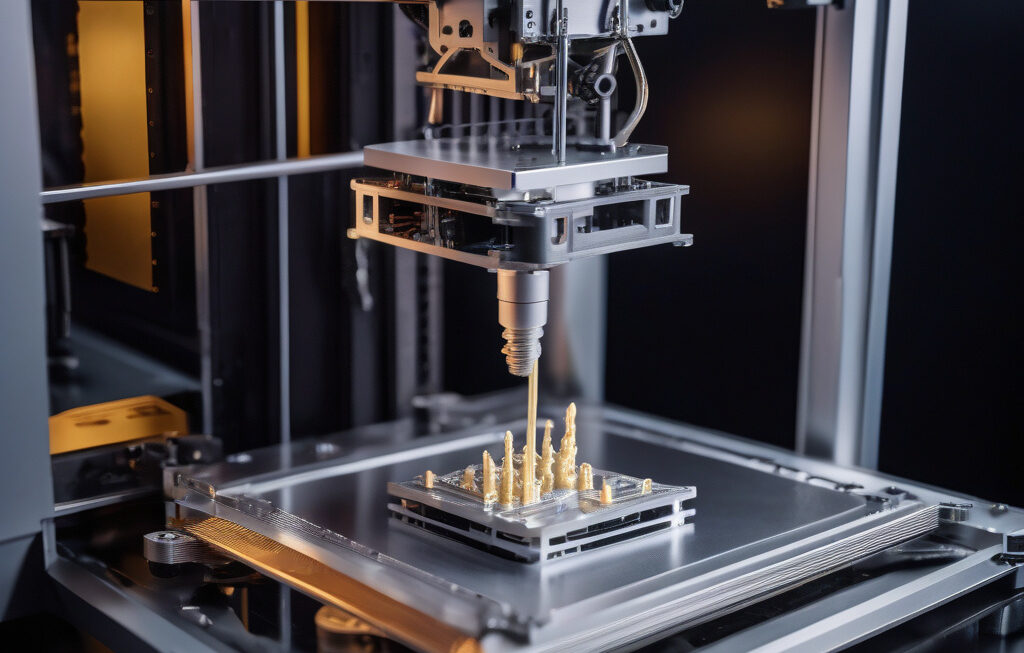

The key innovation behind this new 3D printing method lies in the use of advanced materials such as carbon fiber composites and titanium alloys. By combining these materials with a specialized printing process, researchers have been able to create ultra-strong structures that outperform traditional manufacturing techniques. These new materials exhibit exceptional strength-to-weight ratios, making them ideal for applications where durability and performance are critical.

One of the most significant advantages of this new 3D printing method is its ability to produce complex geometries that are impossible to achieve with conventional manufacturing processes. By precisely controlling the deposition of materials layer by layer, researchers can create intricate designs that maximize strength and minimize weight. This level of customization opens up a world of possibilities for engineers and designers, allowing them to create components that are perfectly tailored to their specific requirements.

In addition to their exceptional strength, the materials produced using this new 3D printing method also exhibit outstanding resistance to a wide range of environmental factors. From extreme temperatures to corrosive chemicals, these materials have been proven to maintain their structural integrity under the most challenging conditions. This makes them ideal for use in harsh environments where traditional materials would quickly degrade or fail.

The potential applications of this new 3D printing technology are vast and varied. In the energy sector, these ultra-strong materials could be used to create more efficient and durable components for renewable energy systems, such as wind turbines and solar panels. In the aerospace industry, they could enable the production of lighter and stronger aircraft parts, leading to improved fuel efficiency and performance. And in the automotive sector, these materials could be used to manufacture safer and more durable vehicles, reducing the overall weight and increasing energy efficiency.

As researchers continue to refine this new 3D printing method and explore its capabilities, the possibilities for innovation are virtually endless. By pushing the boundaries of what is possible with advanced materials and manufacturing techniques, they are paving the way for a new era of high-performance engineering. With ultra-strong materials that can resist 20 times more pressure than conventional options, the future looks brighter and stronger than ever before.

In conclusion, the development of this new 3D printing method represents a significant leap forward in the field of materials science and engineering. By harnessing the power of advanced materials and innovative manufacturing techniques, researchers have created a technology that has the potential to reshape industries and drive innovation across a wide range of applications. The ultra-strong materials produced using this method offer unparalleled strength, durability, and performance, making them ideal for the most demanding challenges of the modern world.

3D Printing, Ultra-Strong Materials, Advanced Manufacturing, Engineering Innovation, High-Performance Applications