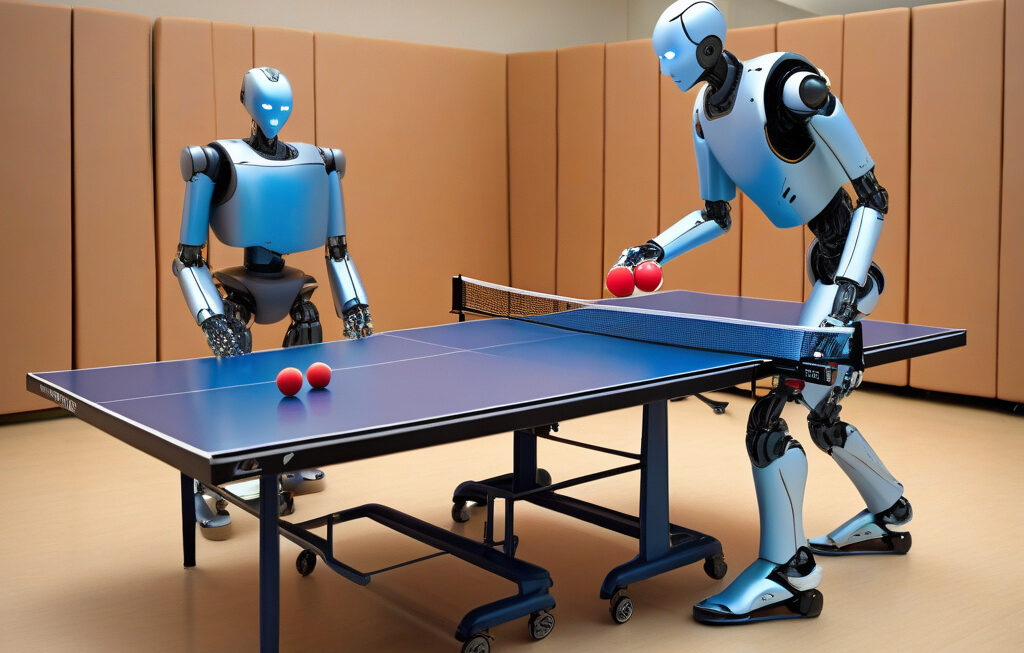

World’s first fully 3D-printed autonomous robot made from recycled materials

In a significant step forward for sustainable robotics, a fully 3D-printed autonomous logistics robot has emerged as a groundbreaking innovation. This robot not only showcases cutting-edge technology but also highlights a strong commitment to environmental sustainability by being constructed entirely from recycled materials.

The integration of 3D printing technology in robotics is not a new concept. However, the utilization of this advanced manufacturing technique to create a fully autonomous robot sets a new standard in the field. By leveraging 3D printing, the production process becomes more efficient, cost-effective, and customizable. This approach allows for the seamless integration of intricate design elements that are essential for the robot’s autonomous functionality.

What sets this particular robot apart is its composition of recycled materials. In an era where environmental consciousness is paramount, the use of recycled plastics and metals in the construction of the robot underscores a dedication to sustainability. Not only does this innovation reduce the reliance on virgin materials, but it also addresses the pressing issue of plastic waste that plagues our planet.

The implications of this development extend beyond just the realm of robotics. It serves as a testament to the endless possibilities that arise when technology and sustainability converge. By demonstrating that high-performance robots can be created from recycled materials, this innovation challenges traditional manufacturing practices and paves the way for a more eco-friendly future.

Furthermore, the autonomy of this robot adds another layer of sophistication to its design. Equipped with advanced sensors, artificial intelligence, and machine learning capabilities, the robot can navigate its environment, make decisions, and perform tasks with minimal human intervention. This level of autonomy not only enhances efficiency but also opens up a myriad of applications across industries, from warehouse logistics to healthcare and beyond.

The journey towards creating the world’s first fully 3D-printed autonomous robot from recycled materials was undoubtedly filled with challenges. From optimizing the design for 3D printing to ensuring the durability and reliability of recycled materials, the project demanded a high level of innovation and ingenuity. However, the end result speaks for itself – a cutting-edge robot that not only meets the demands of modern technology but also upholds a commitment to sustainability.

As we look to the future, it is innovations like these that inspire hope and drive progress. By pushing the boundaries of what is possible in robotics and sustainable manufacturing, we inch closer to a world where technology coexists harmoniously with the environment. The world’s first fully 3D-printed autonomous robot made from recycled materials is not just a feat of engineering; it is a symbol of a brighter, more sustainable tomorrow.

sustainability, robotics, 3D printing, autonomous technology, recycled materials