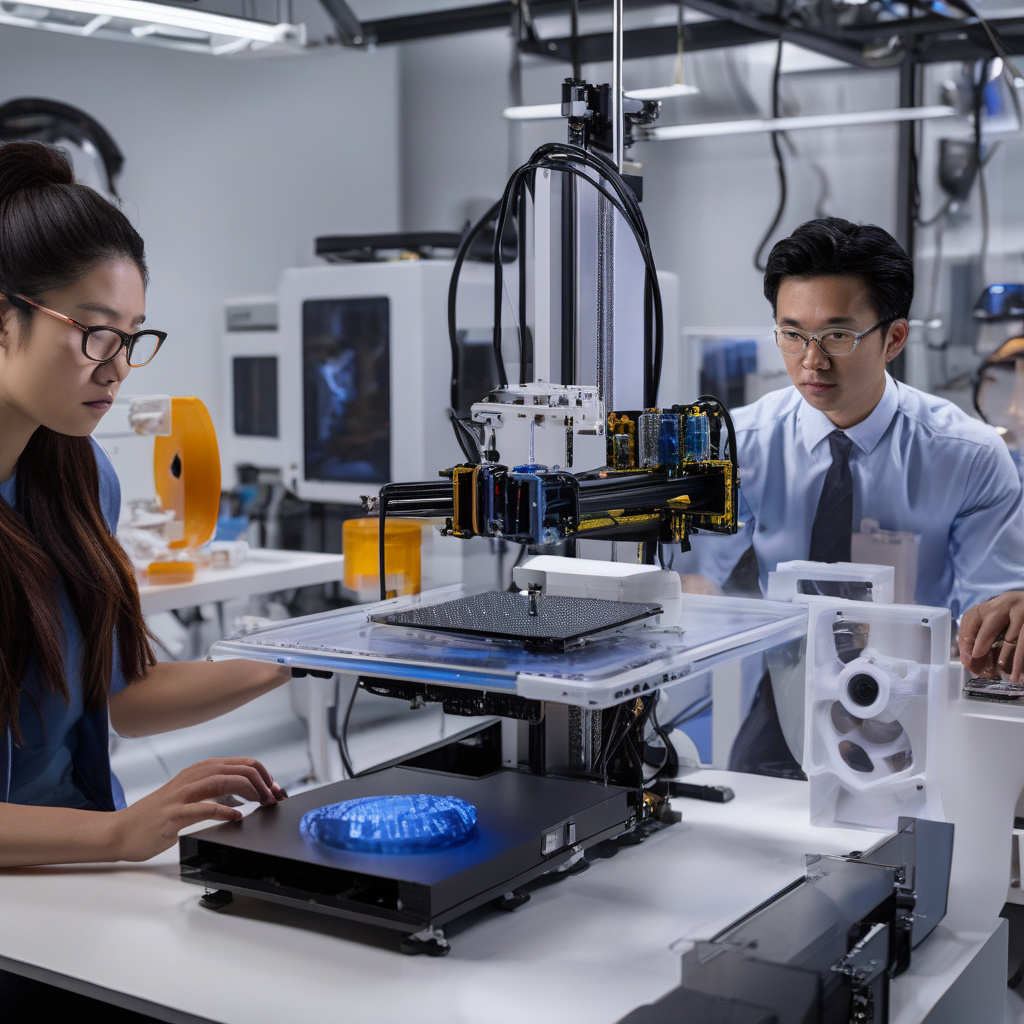

New Research by US Engineers Improves Strength Prediction in 3D Printing

Additive manufacturing (AM) offers several benefits over traditional methods as it can produce durable parts with complex geometries at a faster rate and lower cost. However, one of the challenges in 3D printing has been accurately predicting the strength of the printed parts. This is crucial, especially in industries like aerospace and automotive, where the structural integrity of components is paramount.

Recently, a team of engineers from the United States has made significant strides in improving the strength prediction in 3D printing. By combining advanced modeling techniques with comprehensive experimental testing, the researchers were able to develop a more precise method for assessing the mechanical properties of additively manufactured parts.

The traditional approach to predicting the strength of 3D printed parts involves using simple models that may not account for the complexities of the printing process. This can lead to discrepancies between the predicted and actual strength of the components. To address this issue, the US engineers utilized sophisticated computer simulations to simulate the printing process and predict the material properties at a microstructural level.

Through their research, the engineers were able to identify key factors that influence the strength of 3D printed parts, such as the orientation of the printed layers, the density of the infill structure, and the presence of defects or imperfections. By incorporating these factors into their predictive models, the researchers achieved a much higher level of accuracy in determining the mechanical performance of the printed components.

The implications of this research are significant for the additive manufacturing industry. By improving the ability to predict the strength of 3D printed parts, manufacturers can design components that meet the required performance criteria with greater confidence. This not only enhances the reliability of the printed parts but also opens up new possibilities for using 3D printing in critical applications where safety and durability are paramount.

In addition to enhancing strength prediction, the research by the US engineers also paves the way for optimizing the design of 3D printed parts for specific applications. By understanding how different printing parameters affect the mechanical properties of the components, manufacturers can fine-tune their printing processes to achieve the desired performance characteristics. This level of control and customization is a key advantage of additive manufacturing and can lead to more efficient and innovative designs.

Overall, the work done by the US engineers represents a significant advancement in the field of 3D printing. By bridging the gap between theoretical predictions and experimental results, they have demonstrated the potential to revolutionize the way we approach additive manufacturing. As this research continues to evolve, we can expect to see even greater improvements in the strength, reliability, and performance of 3D printed parts, driving further innovation across a wide range of industries.

#3DPrinting, #AdditiveManufacturing, #Engineering, #StrengthPrediction, #USResearchers