“Revolutionizing Aircraft Engines: The Impact of New 3,632°F Metal Alloy on Fuel Efficiency”

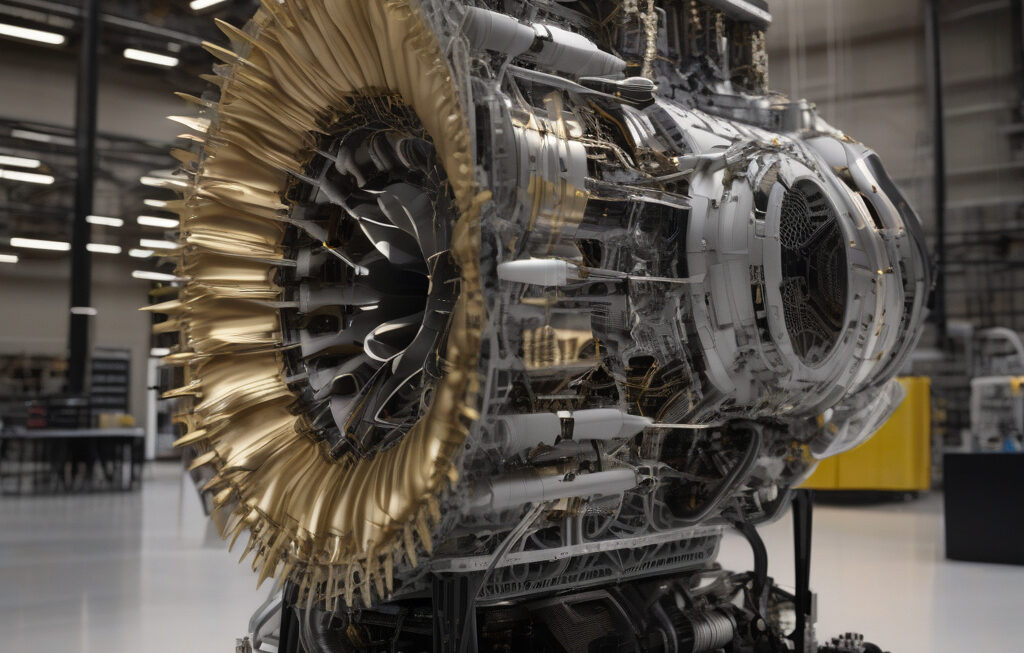

Future designs of aircraft engines and gas turbines may soon see a significant improvement. Researchers have developed a new metal alloy capable of withstanding extreme temperatures of up to 3,632°F (2,000°C), paving the way for more efficient and powerful engines in the aviation industry.

This groundbreaking metal alloy, composed of nickel, tantalum, and aluminum, exhibits exceptional heat resistance and mechanical strength, making it an ideal candidate for high-temperature applications. By utilizing this innovative material in the construction of aircraft engines, manufacturers can enhance fuel efficiency, reduce emissions, and ultimately improve the overall performance of aircraft.

One of the key benefits of this new metal alloy is its ability to withstand temperatures that far exceed the limits of conventional materials currently used in engine components. By operating at higher temperatures, engines can achieve greater thermal efficiency, resulting in reduced fuel consumption and lower operating costs for airlines.

In addition to its impressive heat resistance, the new metal alloy offers superior mechanical properties, including high strength and durability. This allows for the design of lighter and more compact engine components, further contributing to fuel savings and increased efficiency during flight.

Furthermore, the use of this advanced metal alloy in aircraft engines can lead to a significant reduction in emissions, as engines operating at higher temperatures produce fewer harmful pollutants. With sustainability and environmental impact becoming increasingly important in the aviation industry, this new material offers a promising solution for addressing these concerns.

The development of this 3,632°F metal alloy represents a major technological advancement in the field of aerospace engineering. By pushing the boundaries of material science and engineering, researchers have opened up new possibilities for the design and manufacturing of next-generation aircraft engines that are more efficient, environmentally friendly, and cost-effective.

As the aviation industry continues to evolve and strive for greater efficiency, innovations like the new metal alloy are essential for driving progress and meeting the challenges of the future. By incorporating this cutting-edge material into engine technology, manufacturers can elevate performance standards and set new benchmarks for fuel efficiency in the skies.

In conclusion, the introduction of the new 3,632°F metal alloy has the potential to revolutionize the way aircraft engines are designed and operated. With its unparalleled heat resistance, mechanical strength, and environmental benefits, this innovative material is poised to transform the aviation industry and pave the way for a more sustainable and efficient future of air travel.

fuel efficiency, aircraft engines, metal alloy, aerospace engineering, technological innovation