World’s first Near-Zero CO2 Steel Made with Green Hydrogen Revolutionizes Sustainable Manufacturing

A Swedish-American firm has announced that its steel, enhanced with hydrogen-reduced iron, marks a significant milestone in the realm of sustainable manufacturing. This groundbreaking development is poised to revolutionize the steel industry by drastically reducing carbon emissions and paving the way for a greener future.

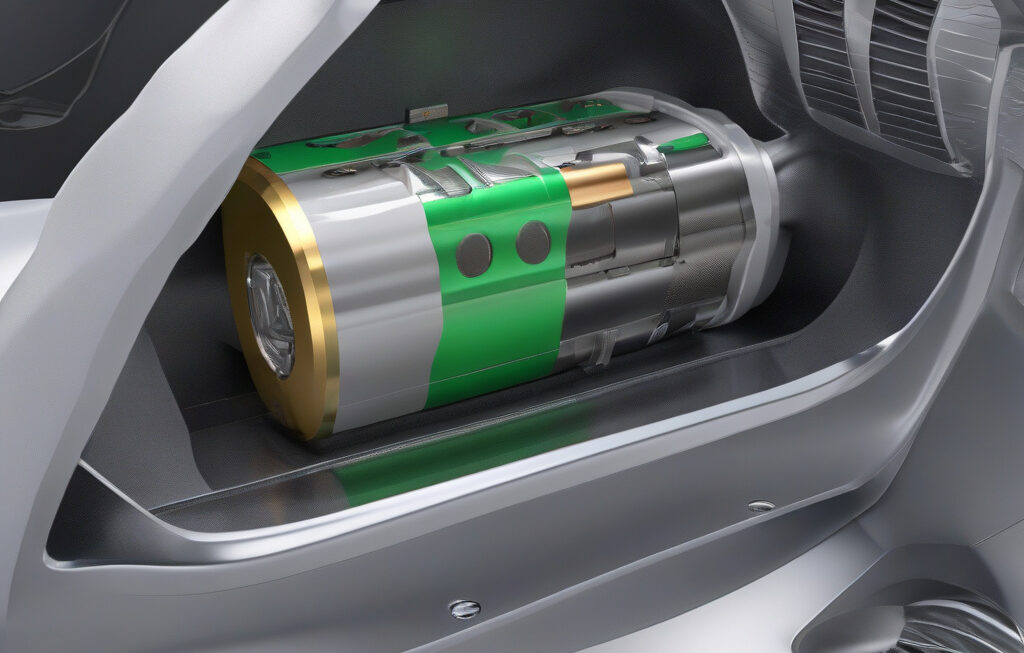

The innovative process involves the utilization of green hydrogen, a clean form of energy produced through electrolysis using renewable sources such as wind or solar power. By harnessing the power of green hydrogen to reduce iron ore into metal, the traditional method of steel production, which is notorious for its high carbon footprint, is being transformed.

The implications of this advancement are far-reaching. Steel is a fundamental building block of modern society, used in everything from infrastructure and transportation to household appliances and machinery. However, the traditional steelmaking process is one of the largest contributors to global carbon dioxide emissions. By introducing near-zero CO2 steel made with green hydrogen into the market, the industry has the potential to make a significant impact in the fight against climate change.

In addition to its environmental benefits, near-zero CO2 steel also offers economic advantages. As the world shifts towards a more sustainable future, consumers and investors are increasingly prioritizing environmentally friendly products and technologies. Companies that embrace green practices and invest in sustainable innovations are not only meeting the demands of today’s market but also future-proofing their businesses against regulatory changes and shifting consumer preferences.

Furthermore, the adoption of near-zero CO2 steel is a testament to the power of collaboration and innovation in driving positive change. The Swedish-American firm’s success in developing this groundbreaking technology underscores the importance of cross-border partnerships and knowledge sharing in tackling global challenges such as climate change.

As the demand for sustainable products continues to rise, it is crucial for industries to embrace green technologies and practices. The near-zero CO2 steel made with green hydrogen represents a significant step forward in the journey towards a more sustainable and carbon-neutral future. By investing in innovative solutions and prioritizing environmental stewardship, companies can not only reduce their carbon footprint but also position themselves as leaders in the transition to a low-carbon economy.

In conclusion, the development of near-zero CO2 steel made with green hydrogen is a game-changer for the steel industry and a shining example of how innovation can drive sustainable development. By leveraging clean energy sources and reimagining traditional manufacturing processes, companies can reduce their environmental impact while meeting the growing demand for sustainable products. This transformative technology serves as a beacon of hope in the fight against climate change, demonstrating that a greener, more sustainable future is within reach.

#SustainableSteel, #GreenHydrogen, #CarbonNeutral, #InnovativeManufacturing, #ClimateAction