Ultra-Small Microchips: Precision at 229 Nanometers

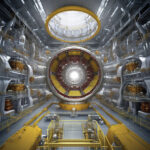

Johns Hopkins researchers have unveiled new materials and a process that could push the boundaries of microchip technology to new frontiers. In a world where smaller, faster, and more powerful devices are the norm, the development of ultra-small microchips with circuits carved at a remarkable 229-nanometer precision is a significant breakthrough.

The traditional method of creating microchips involves photolithography, a process where light is used to transfer circuit patterns onto silicon wafers. However, this process has its limitations when it comes to achieving smaller feature sizes. With the demand for increasingly compact and efficient electronic devices on the rise, researchers at Johns Hopkins have been exploring alternative techniques to meet these challenges.

The key to this groundbreaking advancement lies in the development of new materials that are capable of finer patterning. By using a process known as block copolymer lithography, researchers are able to achieve circuit patterns at a precision of 229 nanometers, which is significantly smaller than the current industry standard.

Block copolymers are self-assembling materials composed of two or more polymer chains with different properties. By harnessing the unique characteristics of these materials, researchers can create intricate patterns at the nanoscale level with unprecedented accuracy.

This breakthrough has the potential to revolutionize the semiconductor industry by enabling the production of ultra-small microchips with higher transistor density and faster processing speeds. These advancements could pave the way for a new generation of electronic devices that are not only smaller and more energy-efficient but also more powerful and versatile.

In addition to the technical advantages of this new approach, there are also significant cost benefits to be gained. By streamlining the manufacturing process and reducing the number of required steps, researchers can lower production costs and increase overall efficiency.

Furthermore, the implications of this breakthrough extend beyond the realm of microchip technology. The development of ultra-small microchips with circuits carved at 229-nanometer precision could have far-reaching applications in fields such as healthcare, telecommunications, and artificial intelligence.

For example, in the healthcare industry, these advanced microchips could be used to develop implantable devices that are smaller and more biocompatible, leading to more effective treatments and improved patient outcomes. In telecommunications, the increased processing power of these microchips could enable faster data transmission and more reliable networks. And in the field of artificial intelligence, the ability to pack more transistors into a smaller space could lead to significant advancements in machine learning and complex algorithms.

As technology continues to advance at a rapid pace, the development of ultra-small microchips with circuits carved at 229-nanometer precision represents a major leap forward in the world of semiconductor manufacturing. By pushing the boundaries of what is possible, researchers at Johns Hopkins are shaping the future of electronics and paving the way for a new era of innovation and discovery.

#MicrochipTechnology, #SemiconductorIndustry, #Nanotechnology, #Innovation, #JohnsHopkinsResearchers