3D-Printed Resin ‘Shocks’ Scientists with Rubber-Like Flex, Plastic-Like Strength

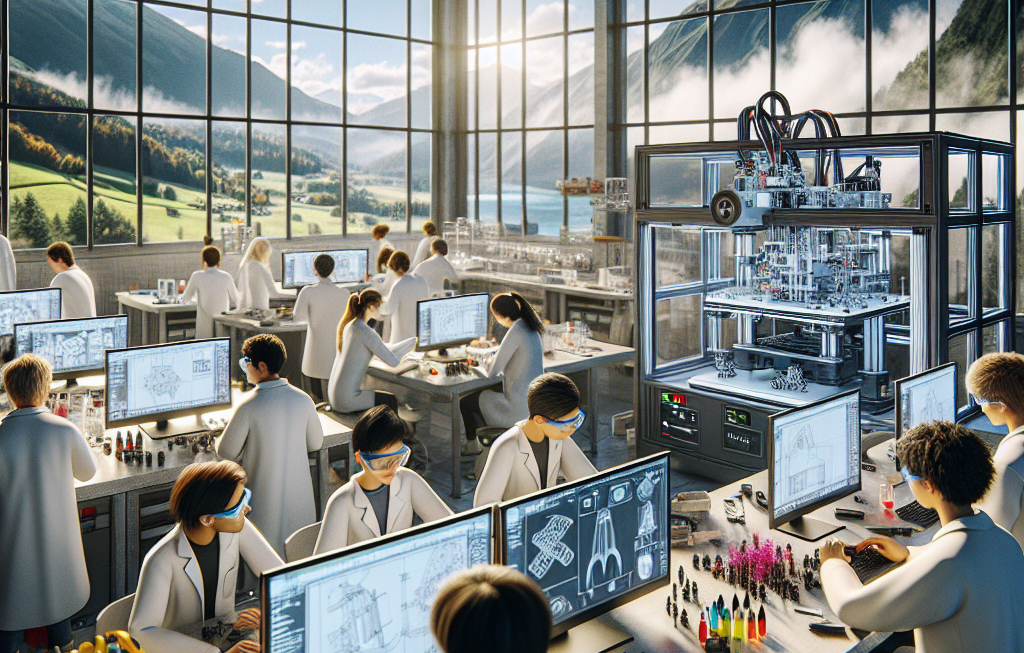

Researchers from the University of Texas at Austin have developed a fast and precise 3D printing process that has stunned the scientific community with its innovative characteristics. This groundbreaking technique involves the use of resin that possesses a remarkable combination of rubber-like flexibility and plastic-like strength, pushing the boundaries of what was previously thought possible in 3D printing technology.

Traditionally, 3D printing has been associated with either rigid or flexible materials, but rarely both. However, the resin created by the researchers at the University of Texas at Austin challenges this norm by offering a unique blend of properties that opens up a world of possibilities for various industries, including aerospace, automotive, healthcare, and beyond.

One of the most impressive features of this 3D-printed resin is its exceptional flexibility, which rivals that of rubber. This means that objects produced with this resin can bend, stretch, and compress without losing their structural integrity. Imagine a 3D-printed object that can be twisted and turned without breaking – the potential applications for such a material are endless.

In addition to its rubber-like flexibility, the resin also boasts plastic-like strength, making it incredibly durable and resistant to wear and tear. This means that objects printed with this resin can withstand heavy loads, impacts, and harsh environmental conditions, making them suitable for a wide range of practical applications.

The secret behind the remarkable properties of this resin lies in its unique chemical composition and the precise 3D printing process developed by the researchers. By carefully controlling the printing parameters, such as curing time and exposure to light, the team was able to achieve the perfect balance of flexibility and strength in the final printed objects.

The potential impact of this 3D-printed resin is enormous. In the aerospace industry, for example, it could be used to create lightweight yet strong components for aircraft and spacecraft. In the healthcare field, it could revolutionize the production of custom prosthetics and medical devices. In the automotive sector, it could lead to the development of safer and more efficient vehicles.

Furthermore, the fast and precise nature of the 3D printing process means that manufacturers can produce complex objects quickly and cost-effectively, opening up new opportunities for innovation and customization. This resin could truly change the way we think about 3D printing and its capabilities.

As the scientific community continues to explore the potential of this groundbreaking technology, one thing is clear – the future of 3D printing looks more exciting than ever before. With the development of materials like this remarkable resin, we are one step closer to unlocking a new era of manufacturing possibilities.

In conclusion, the 3D-printed resin created by the researchers at the University of Texas at Austin represents a significant leap forward in the world of additive manufacturing. Its unique combination of rubber-like flexibility and plastic-like strength has the potential to revolutionize multiple industries and pave the way for a new wave of innovative applications. The possibilities are endless, and the future is bright for this groundbreaking technology.

3D printing, Resin technology, Innovation, Scientific breakthrough, Additive manufacturing