Orbit Supercharges Spot Robot Dog with AI to Predict Failures Before They Strike

Advancing predictive industrial maintenance, Boston Dynamics has introduced the latest version of Orbit—its intelligent automation platform that aims to revolutionize the way companies approach maintenance operations. By integrating cutting-edge artificial intelligence (AI) technology into its iconic Spot robot dog, Boston Dynamics is taking a significant step towards predictive maintenance, allowing businesses to identify and address issues before they escalate into costly failures.

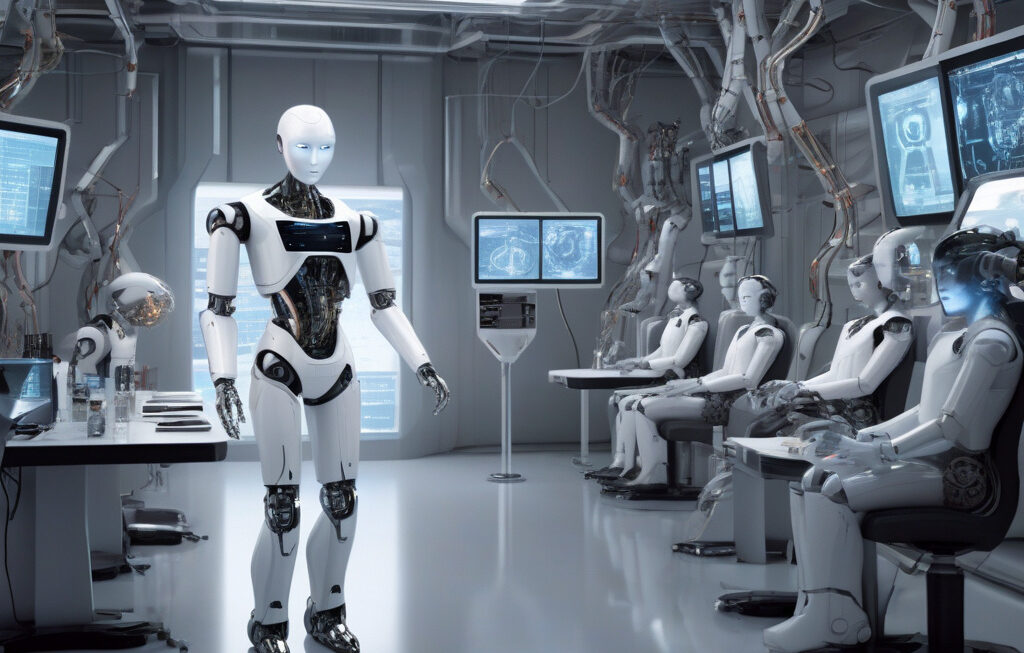

The marriage of Orbit’s AI capabilities with Spot’s agility and versatility creates a powerful tool that can navigate complex industrial environments with ease while continuously gathering and analyzing data. This data is then processed in real-time to detect patterns, anomalies, and potential issues that may lead to equipment breakdowns or malfunctions. By leveraging AI to predict failures before they occur, companies can proactively schedule maintenance tasks, optimize resources, and minimize downtime, ultimately saving time and money.

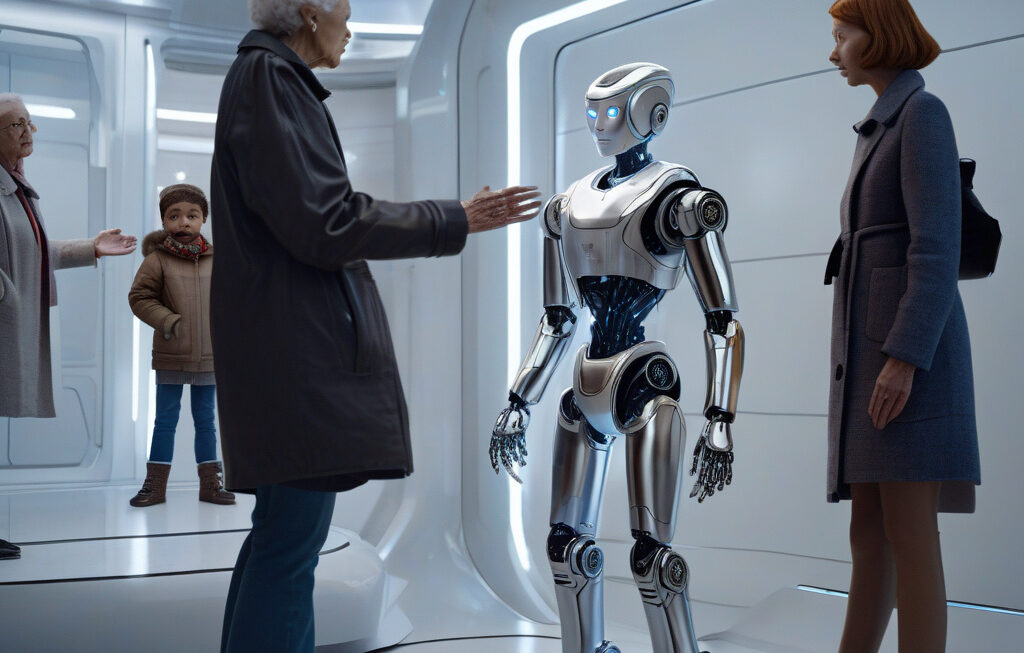

One of the key advantages of using Spot equipped with Orbit is its ability to access hard-to-reach or hazardous areas without putting human workers at risk. Spot can autonomously patrol facilities, inspect machinery, and gather data in environments where sending human personnel would be dangerous or impractical. This not only enhances worker safety but also ensures that maintenance tasks are carried out efficiently and effectively.

Moreover, the integration of AI technology allows Spot to learn from past incidents and continuously improve its predictive capabilities. By analyzing historical data and performance trends, Spot can refine its algorithms and become more accurate in identifying potential issues before they manifest. This iterative process of learning and adaptation ensures that Spot remains at the forefront of predictive maintenance solutions, constantly evolving to meet the needs of modern industries.

In addition to its predictive maintenance capabilities, Spot with Orbit offers a range of other functionalities that can streamline operations and enhance overall efficiency. From 3D mapping and remote monitoring to automated data collection and reporting, Spot can serve as a versatile tool for various industrial applications, providing valuable insights and facilitating data-driven decision-making.

As industries continue to embrace digital transformation and automation, the demand for advanced predictive maintenance solutions like Spot with Orbit is expected to grow. By harnessing the power of AI and robotics, companies can gain a competitive edge by maximizing uptime, reducing maintenance costs, and improving overall operational performance. The era of reactive maintenance is gradually giving way to proactive and predictive approaches, where machines like Spot play a crucial role in ensuring the reliability and longevity of industrial assets.

In conclusion, Boston Dynamics’ integration of AI technology into Spot through the Orbit platform represents a significant leap forward in the field of predictive maintenance. By combining the agility and mobility of Spot with the analytical prowess of AI, companies can now detect and address potential failures before they impact operations, ushering in a new era of efficiency and reliability in industrial maintenance.

#BostonDynamics, #SpotRobotDog, #PredictiveMaintenance, #AIInnovation, #IndustrialAutomation