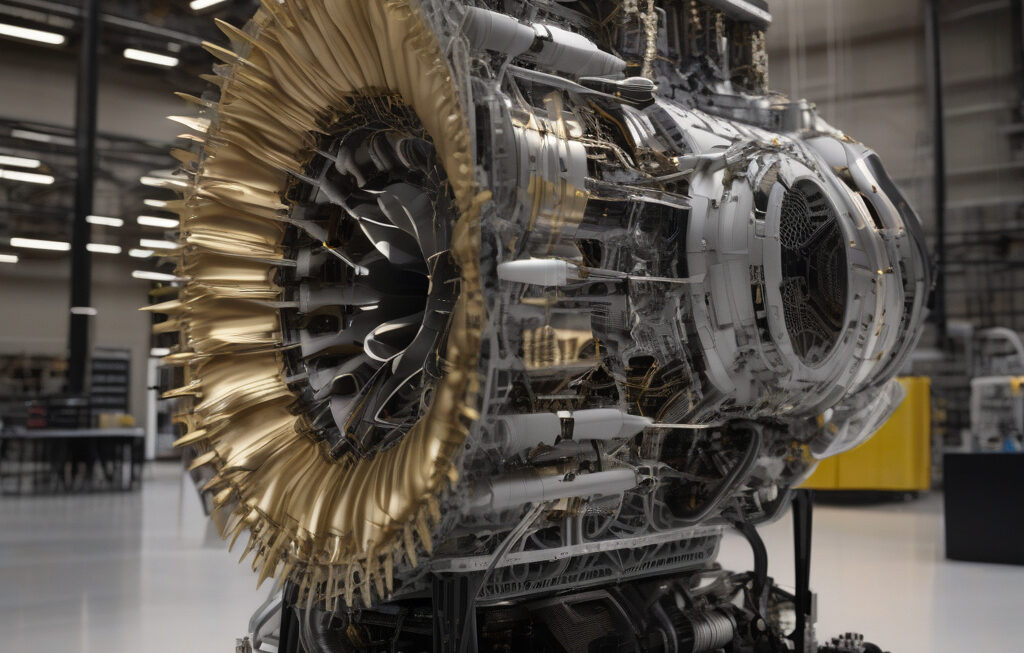

“Pore No More: US Scientists Develop Real-Time Defect Detection for 3D Metal Printing”

Scientists from the federally funded Argonne National Laboratory in Illinois and the University of Virginia have made a groundbreaking advancement in the realm of 3D metal printing. With the increasing popularity of additive manufacturing in various industries, the need for high-quality, defect-free printed parts has become more critical than ever. One of the significant challenges faced in metal 3D printing is the occurrence of pores, which are tiny gas bubbles trapped within the material during the printing process. These pores can weaken the structural integrity of the printed parts, leading to potential failures in real-world applications.

To address this issue, the team of researchers has developed a real-time defect detection system that can identify and monitor the formation of pores as the metal part is being printed. By using advanced imaging techniques and machine learning algorithms, the system can detect even the smallest pores with high accuracy, allowing operators to take corrective actions immediately. This real-time monitoring not only ensures the quality of the printed parts but also saves time and resources by minimizing the need for post-processing inspections and rework.

The implications of this breakthrough are significant for industries such as aerospace, automotive, and healthcare, where the demand for complex metal components with high mechanical properties is rapidly growing. By eliminating the guesswork involved in detecting defects post-printing, manufacturers can now produce parts with greater confidence and consistency. This not only enhances the overall quality of the products but also reduces the risk of costly recalls and failures down the line.

Moreover, the real-time defect detection system opens up new possibilities for optimizing the 3D printing process itself. By providing instant feedback on the quality of the printed parts, manufacturers can fine-tune various parameters such as printing speed, temperature, and material composition to further enhance the performance and reliability of the final products. This iterative approach to process optimization paves the way for the development of new alloys, geometries, and functionalities that were previously unattainable with traditional manufacturing methods.

In conclusion, the collaboration between the Argonne National Laboratory and the University of Virginia marks a significant milestone in the advancement of 3D metal printing technology. Their real-time defect detection system not only addresses a critical challenge in the industry but also sets a new standard for quality assurance and process control. As additive manufacturing continues to revolutionize the way we design and produce metal parts, innovations like this will play a crucial role in shaping the future of manufacturing across various sectors.

#3DPrinting, #MetalPrinting, #DefectDetection, #AdditiveManufacturing, #QualityAssurance