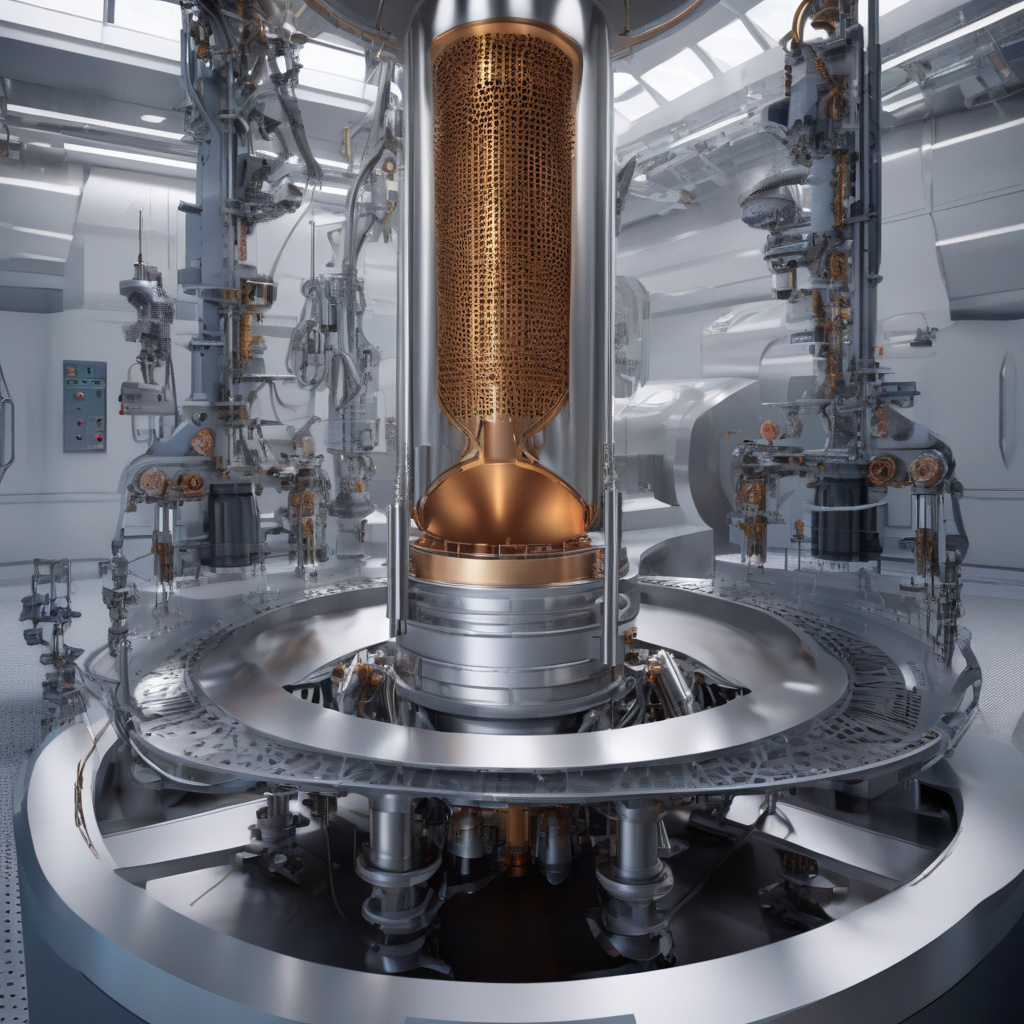

World’s first 3D-printed titanium rocket part passes extreme cryogenic pressure test

A team of scientists at the Korea Institute of Industrial Technology (KITECH) has announced that they have achieved a remarkable milestone in the field of aerospace engineering. Their groundbreaking accomplishment involves the successful testing of the world’s first 3D-printed titanium rocket part under extreme cryogenic conditions.

The 3D-printed titanium rocket part, a crucial component of modern aerospace technology, underwent rigorous testing to assess its performance under intense cryogenic pressure. Cryogenic testing is essential to ensure that materials can withstand the extreme cold temperatures experienced during space travel. The successful outcome of this test represents a significant advancement in the use of additive manufacturing techniques for aerospace applications.

The use of 3D printing technology to create aerospace components offers a host of benefits, including increased design flexibility, reduced production costs, and faster prototyping. Traditional manufacturing methods often involve complex machining processes that can be time-consuming and expensive. In contrast, 3D printing allows for the rapid production of intricate geometries with minimal material waste, making it an attractive option for the aerospace industry.

Titanium is a preferred material for aerospace applications due to its exceptional strength-to-weight ratio and resistance to corrosion. By successfully 3D printing a titanium rocket part that can withstand extreme cryogenic conditions, the team at KITECH has demonstrated the viability of this innovative manufacturing approach for producing high-performance aerospace components.

This achievement has far-reaching implications for the future of space exploration and commercial satellite deployment. The ability to reliably manufacture complex titanium parts using 3D printing technology opens up new possibilities for improving the efficiency and reliability of rocket propulsion systems. As the demand for small satellite launches and space tourism continues to grow, innovations in aerospace manufacturing will play a crucial role in shaping the future of the industry.

In addition to its applications in aerospace, 3D printing technology has the potential to revolutionize a wide range of industries, from healthcare to automotive. The ability to rapidly prototype and produce custom parts with intricate designs offers unprecedented opportunities for innovation and cost savings. As 3D printing techniques continue to advance, we can expect to see even more groundbreaking developments in the manufacturing sector.

The successful testing of the world’s first 3D-printed titanium rocket part under extreme cryogenic conditions represents a major step forward in the evolution of additive manufacturing for aerospace applications. This achievement underscores the importance of pushing the boundaries of technology to unlock new possibilities and drive progress in the field of engineering and design.

In conclusion, the team of scientists at KITECH has set a new standard for innovation in aerospace engineering with their groundbreaking work on 3D-printed titanium rocket parts. By demonstrating the viability of this cutting-edge manufacturing technique under extreme cryogenic conditions, they have paved the way for a new era of aerospace technology that promises to revolutionize space exploration and satellite deployment.

aerospace, 3Dprinting, innovation, titaniumrocket, KITECH