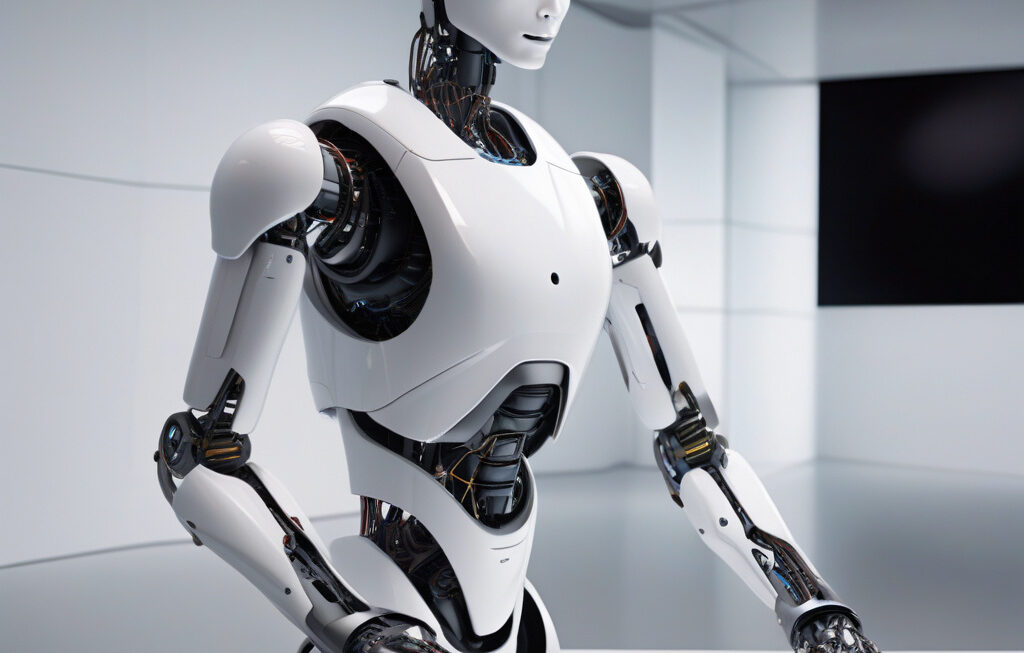

FlyingToolbox: Revolutionizing Robotics with Mid-Air Tool Swapping

Researchers at Westlake University in China have developed a new system that allows drones to swap tools mid-air with unprecedented precision. This groundbreaking technology, known as FlyingToolbox, is set to revolutionize the field of robotics by streamlining processes and increasing efficiency like never before.

Traditionally, when a drone needs to change its tool or payload, it has to land, undergo the necessary modifications, and then take off again. This process not only consumes valuable time but also requires a skilled operator to ensure a successful tool swap. However, with the introduction of FlyingToolbox, this cumbersome method is a thing of the past.

The system works by equipping drones with specialized gripping mechanisms that can securely hold different tools. When a tool change is required, another drone equipped with the desired tool approaches the first drone. Using advanced computer vision and motion planning algorithms, the FlyingToolbox system ensures precise alignment between the two drones, allowing for a seamless transfer of the tool from one drone to another.

One of the key advantages of FlyingToolbox is its ability to facilitate tool swaps in challenging environments where landing may be impractical or even impossible. For example, in search and rescue missions or infrastructure inspections, drones equipped with the FlyingToolbox system can now exchange thermal cameras for gas sensors or LiDAR scanners without interrupting their operations.

Moreover, the precision of the tool swapping process minimizes the risk of damage to both the drones and the tools themselves. This not only reduces maintenance costs but also extends the overall lifespan of the equipment, making FlyingToolbox a cost-effective solution for various industries.

The implications of this technology are far-reaching. In the construction industry, drones can seamlessly transition between different tasks such as aerial surveying, 3D mapping, and equipment transport by simply swapping tools mid-air. Similarly, in agriculture, drones can change payloads from seeding devices to crop monitoring sensors without the need for manual intervention.

Furthermore, FlyingToolbox opens up new possibilities for drone swarm applications, where multiple drones work together to accomplish complex tasks. By enabling drones to exchange tools autonomously, the system paves the way for coordinated efforts in disaster response, environmental monitoring, and large-scale infrastructure projects.

As the demand for drone technology continues to grow across various sectors, innovations like FlyingToolbox highlight the importance of enhancing the capabilities of these unmanned aerial vehicles. By introducing seamless tool swapping capabilities, researchers at Westlake University have set a new standard for precision and efficiency in drone operations.

In conclusion, FlyingToolbox represents a significant leap forward in the field of robotics, offering a glimpse into a future where drones can adapt to changing requirements on the fly. With its potential to transform industries and streamline operations, this technology is poised to redefine the way we think about aerial robotics.

#FlyingToolbox, #RoboticsInnovation, #DroneTechnology, #PrecisionToolSwapping, #FutureOfDrones