Humanoid Robots Poised to Revolutionize Manufacturing at US Foxconn Facility Building Nvidia AI Servers

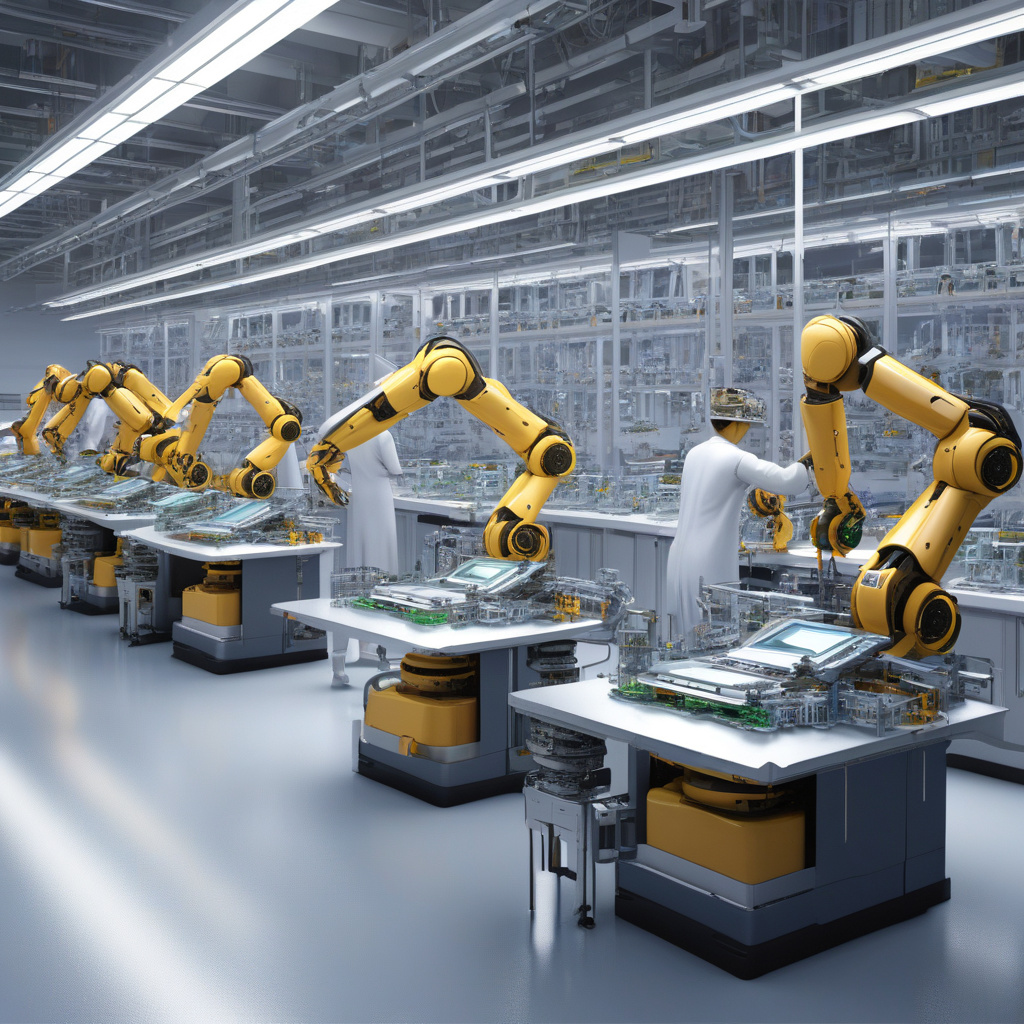

In the realm of manufacturing, a groundbreaking development is on the horizon as discussions unfold between an American firm specializing in powerful GPUs and Foxconn, the global electronics manufacturer. The focal point of these talks is the potential deployment of humanoid robots within a US-based Foxconn facility, tasked with the assembly of Nvidia AI servers. This prospective collaboration marks a significant advancement in the integration of robotics and artificial intelligence within the manufacturing sector, promising to redefine efficiency, precision, and productivity in the production process.

The notion of humanoid robots working alongside human counterparts in industrial settings is no longer confined to the realms of science fiction. With rapid technological advancements and the growing sophistication of robotics, the vision of intelligent machines contributing to manufacturing operations is swiftly materializing. The partnership between the American GPU manufacturer and Foxconn underscores a strategic alignment towards harnessing the capabilities of humanoid robots to streamline the production of cutting-edge technology such as Nvidia AI servers.

The integration of humanoid robots into the manufacturing process offers a myriad of benefits that are poised to revolutionize the industry. One of the primary advantages lies in the enhanced efficiency and precision that robots bring to repetitive and labor-intensive tasks. By leveraging AI-powered robots for assembling Nvidia AI servers, the potential for eliminating errors, reducing production time, and optimizing workflow management becomes significantly amplified. Moreover, the utilization of humanoid robots can lead to cost savings in the long run, as their consistent performance and minimal maintenance requirements translate into higher operational efficiency.

Beyond operational enhancements, the introduction of humanoid robots into the manufacturing ecosystem holds the promise of fostering a safer work environment. By assigning robots to handle tasks that pose potential risks to human workers, such as lifting heavy components or operating in hazardous conditions, the overall safety standards within the facility are elevated. This not only mitigates the likelihood of workplace accidents but also ensures the well-being of employees by reallocating high-risk activities to machines equipped to handle them with precision and reliability.

Furthermore, the collaboration between the American GPU manufacturer and Foxconn in deploying humanoid robots underscores a strategic approach towards staying at the forefront of technological innovation. By embracing automation and AI-driven solutions in the manufacturing process, both companies demonstrate a commitment to staying competitive in an increasingly digitalized landscape. The integration of robots in assembling Nvidia AI servers not only showcases a forward-thinking mindset but also sets a precedent for the industry in leveraging cutting-edge technologies to drive operational excellence.

As the discussions between the American GPU manufacturer and Foxconn progress towards the potential implementation of humanoid robots in manufacturing, the implications of this collaboration reverberate across the industry. The convergence of robotics, artificial intelligence, and manufacturing holds the key to unlocking unprecedented levels of efficiency, precision, and productivity within production facilities. By embracing the transformative power of humanoid robots, companies can position themselves at the vanguard of innovation, setting new standards for excellence in the manufacturing landscape.

In conclusion, the prospect of humanoid robots working alongside human employees at a US-based Foxconn facility to build Nvidia AI servers heralds a new era of manufacturing excellence. The synergy between advanced robotics, artificial intelligence, and industry-leading technology signifies a paradigm shift in how manufacturing processes are conceptualized and executed. As this collaboration unfolds, the potential for increased efficiency, enhanced safety, and technological advancement paves the way for a future where human and machine collaboration sets the stage for unparalleled success in the manufacturing domain.

#HumanoidRobots, #ManufacturingInnovation, #NvidiaAIServers, #FoxconnFacility, #TechnologicalAdvancements