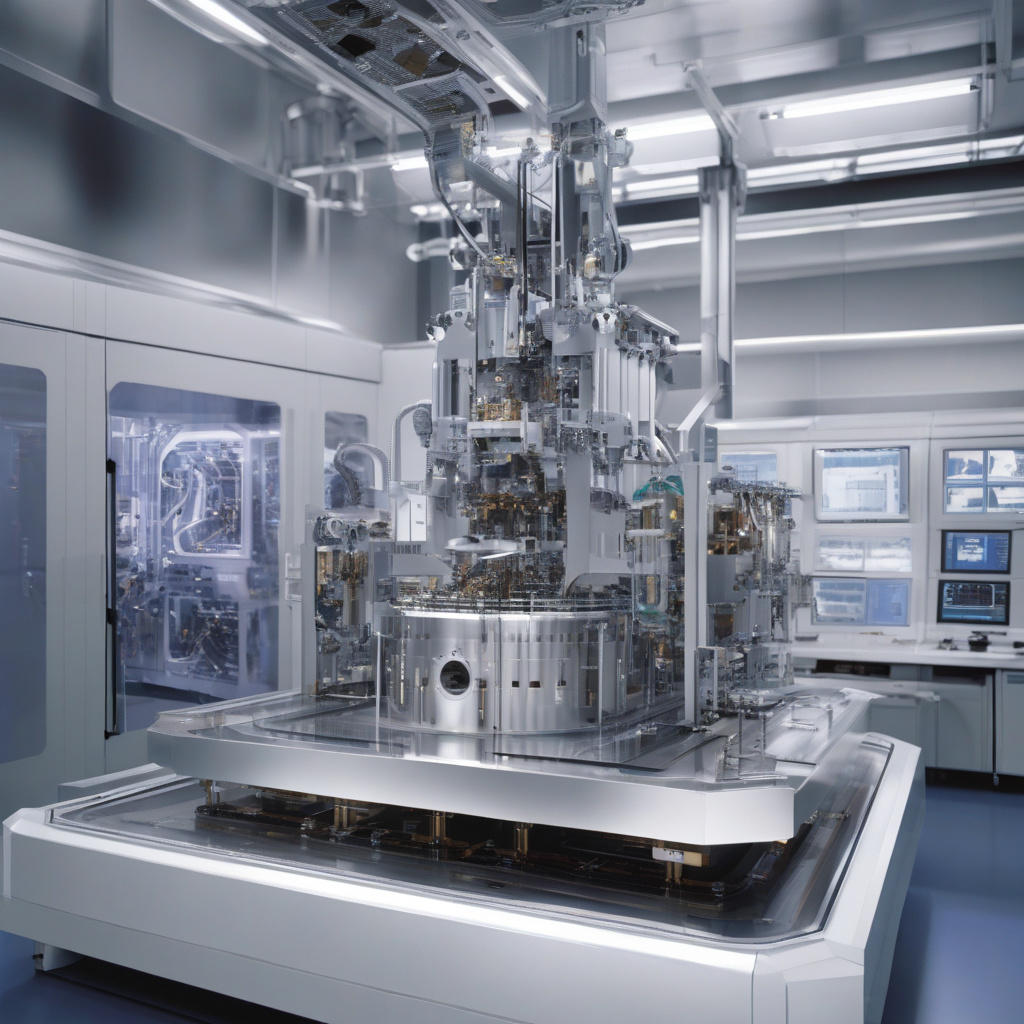

Revolutionizing Chip Making: DirectDrive Plasma Etching Technology

Imagine trying to carve a tiny, complex sculpture into a block the size of your fingernail with absolute precision. This is the incredible challenge that semiconductor manufacturers face when creating the intricate patterns that form the basis of modern computer chips. For over two decades, researchers have been tirelessly working to perfect a technology that could revolutionize this process – DirectDrive plasma etching.

DirectDrive plasma etching technology represents a significant breakthrough in the world of chip making. Traditional etching methods involve using masks to selectively remove material from silicon wafers. However, these masks can degrade over time, leading to imprecise etching and reduced chip quality. DirectDrive plasma etching eliminates the need for masks altogether, allowing for direct and highly accurate patterning of the wafer surface.

One of the key advantages of DirectDrive plasma etching is its ability to achieve sub-nanometer precision. This level of accuracy is crucial for the development of next-generation chips, which feature increasingly smaller and more densely packed components. By eliminating the limitations imposed by masks, DirectDrive technology enables manufacturers to create chips with unprecedented levels of complexity and performance.

Moreover, DirectDrive plasma etching offers significant improvements in terms of efficiency and cost-effectiveness. By streamlining the etching process and reducing the need for multiple masking steps, manufacturers can increase their production throughput and yield, ultimately driving down the overall cost of chip manufacturing. This not only benefits the companies involved but also has the potential to lower the prices of consumer electronics in the long run.

The impact of DirectDrive plasma etching technology extends beyond the realm of chip making. As semiconductor manufacturers adopt this innovative approach, we can expect to see advancements in a wide range of industries, from telecommunications and healthcare to automotive and aerospace. The ability to create smaller, faster, and more energy-efficient chips will pave the way for new and exciting applications that were previously thought to be unattainable.

In conclusion, after two decades of dedicated research and development, DirectDrive plasma etching technology is poised to transform the landscape of chip making. With its unparalleled precision, efficiency, and cost-effectiveness, this revolutionary technology holds the key to unlocking a new era of innovation and progress in the semiconductor industry. As we witness the widespread adoption of DirectDrive plasma etching in the years to come, we can look forward to a future where the boundaries of what is possible continue to be pushed further than ever before.

semiconductor, technology, innovation, precision, efficiency