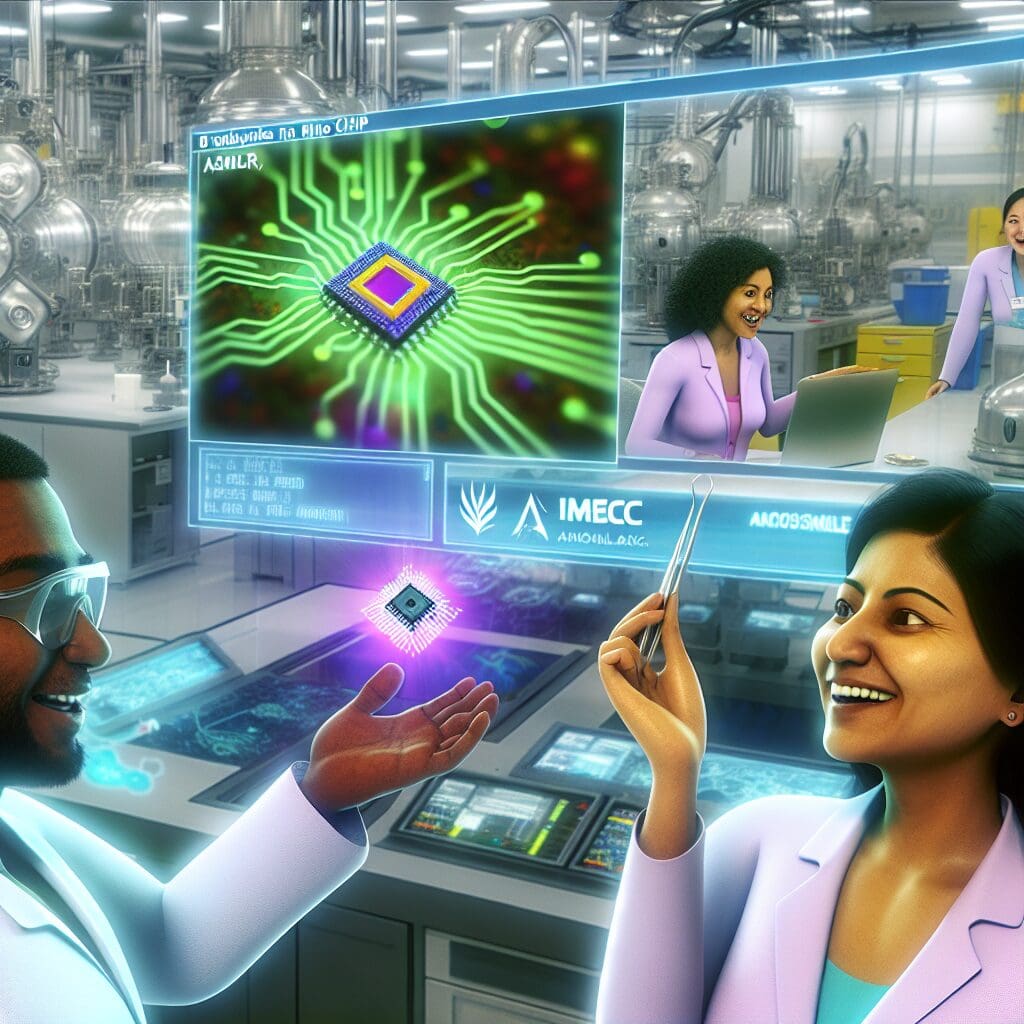

In an impressive development for the semiconductor industry, imec, a leading research and development organization based in Belgium, has partnered with ASML to unveil groundbreaking advancements in chip production. At the heart of this innovation lies ASML’s latest €350 million chip printing machine, which has demonstrated remarkable capabilities in creating complex chip designs with unprecedented precision.

ASML’s pioneering lithography technology, known as extreme ultraviolet (EUV) lithography, has set a new standard in the semiconductor manufacturing process. This technology allows for the fabrication of increasingly smaller chips, essential for powering today’s AI applications and advanced electronic devices. According to imec, the collaboration has already yielded chips that are smaller, faster, and more energy-efficient than ever before, paving the way for enhanced performance in areas like artificial intelligence, data processing, and mobile computing.

This collaboration marks a significant leap forward for both companies, reaffirming their leadership in a highly competitive global market. The successful integration of innovative manufacturing processes signals a positive outlook for the industry, particularly as demand for high-performance chips continues to soar. As companies strive to stay ahead in the race for technological superiority, partnerships like these highlight the importance of collaboration in driving innovation and achieving sustainable growth.

Industry analysts predict that these advancements will not only benefit ASML and imec but will also have ripple effects across various sectors reliant on semiconductor technology, including automotive, healthcare, and telecommunications. With ongoing investments and research to improve chip production, the future of technology appears more promising, opening doors to new possibilities that could transform the business landscape.