Robots with Noses: Swiss Firm’s ANYmal Sniffs Out Gas Leaks at Hazardous Sites

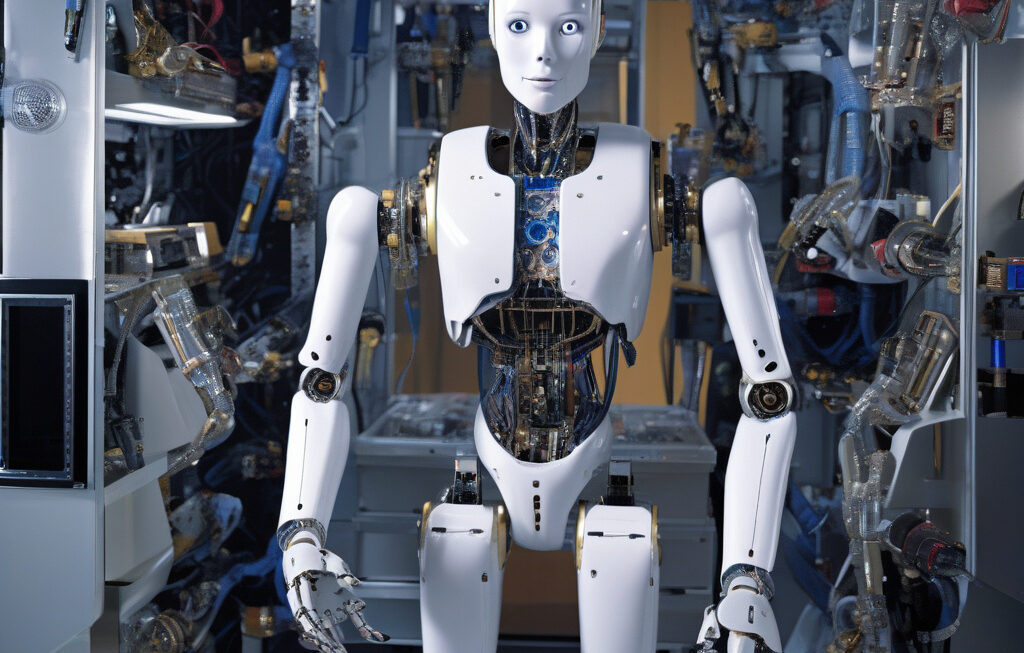

A Switzerland-based tech firm has launched a new tech solution that can help its ANYmal robot detect gas leaks in hazardous environments. This innovative development marks a significant advancement in the field of robotics, particularly in the realm of safety and efficiency in industrial settings.

The ANYmal robot, equipped with a sophisticated “electronic nose,” is designed to navigate challenging terrains and harsh conditions commonly found in industrial facilities such as oil refineries, chemical plants, and gas pipelines. By leveraging its olfactory sensors, the robot can swiftly and accurately detect the presence of gas leaks that may pose risks to human workers and the surrounding environment.

The ability of the ANYmal robot to sniff out gas leaks serves as a prime example of how cutting-edge technology can enhance workplace safety and streamline operations in high-risk industries. Traditionally, gas leak detection has been a labor-intensive and time-consuming process, often requiring human workers to manually inspect vast areas for potential leaks. The introduction of robotic solutions like ANYmal not only mitigates the safety hazards associated with such tasks but also increases the overall efficiency of gas leak detection procedures.

Moreover, the implementation of robots with olfactory capabilities underscores the potential for interdisciplinary collaboration between robotics and sensory technology. By mimicking the sense of smell in robots, engineers and researchers are opening up new possibilities for the application of robotic systems in various real-world scenarios, ranging from industrial inspections to search and rescue missions.

In addition to its gas detection capabilities, the ANYmal robot boasts a range of features that make it a versatile and invaluable asset in industrial settings. Equipped with advanced mobility systems, including four legs that enable agile movement across different terrains, the robot can access hard-to-reach areas with ease. Furthermore, its integration with state-of-the-art sensors and cameras allows for comprehensive data collection and analysis, facilitating informed decision-making by human operators.

The Swiss firm’s development of the ANYmal robot exemplifies the ever-growing synergy between robotics, artificial intelligence, and environmental safety. As industries continue to prioritize worker well-being and regulatory compliance, innovative solutions like the ANYmal robot are poised to revolutionize the way hazardous environments are monitored and managed.

In conclusion, the introduction of robots with noses, such as the ANYmal robot developed by the Switzerland-based tech firm, represents a significant leap forward in the realm of industrial robotics and safety. By harnessing the power of olfactory sensors, these robots offer a reliable and efficient solution for detecting gas leaks in hazardous sites, ultimately enhancing workplace safety and operational effectiveness.

#Robots, #ANYmal, #GasLeaks, #SwissTech, #IndustrialSafety