Safer, Cheaper Lithium Sulfide for Solid-State Batteries: A Breakthrough Process Revolutionizes Cost Efficiency

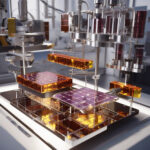

Solid-state batteries have long been hailed as the future of energy storage, promising higher energy densities, faster charging capabilities, and improved safety compared to traditional lithium-ion batteries. However, the widespread adoption of solid-state technology has been hindered by the high cost and limited availability of key components, such as lithium sulfide.

Now, a groundbreaking low-temperature process developed by researchers offers a promising solution to this bottleneck. By slashing the cost of lithium sulfide production, this breakthrough has the potential to accelerate the commercialization of solid-state batteries and drive the next phase of innovation in the electric vehicle and renewable energy sectors.

The traditional method of producing lithium sulfide involves high temperatures and energy-intensive processes, making it a costly and environmentally unfriendly material to work with. In contrast, the new process utilizes innovative techniques that not only reduce production costs but also enhance the material’s performance characteristics.

One of the key advantages of this breakthrough process is its scalability. By optimizing the production parameters, researchers have demonstrated the ability to manufacture lithium sulfide at a larger scale without compromising quality or cost efficiency. This scalability is crucial for meeting the growing demand for solid-state batteries in various industries.

Moreover, the low-temperature nature of the process significantly improves the safety profile of lithium sulfide production. By minimizing the risk of thermal runaway reactions and other hazards associated with high-temperature processes, manufacturers can ensure a safer working environment and reduce the overall cost of safety measures.

In addition to cost savings and safety benefits, the new process also offers performance enhancements that could revolutionize the capabilities of solid-state batteries. By fine-tuning the material properties of lithium sulfide at the nanoscale, researchers have achieved superior electrochemical performance, including higher energy densities and faster charging rates.

The implications of this breakthrough are far-reaching. Electric vehicle manufacturers stand to benefit from the increased energy storage capacity and reduced charging times enabled by cost-effective lithium sulfide. Similarly, the renewable energy sector could leverage the enhanced performance characteristics of solid-state batteries to improve the efficiency and reliability of grid-scale energy storage systems.

As the demand for clean energy solutions continues to grow, innovations like the low-temperature lithium sulfide production process will play a pivotal role in driving the transition to a sustainable energy future. By lowering the barriers to widespread adoption of solid-state battery technology, this breakthrough has the potential to reshape the dynamics of the energy storage market and accelerate the global shift towards decarbonization.

In conclusion, the development of a cost-effective, low-temperature process for producing lithium sulfide represents a significant milestone in the advancement of solid-state battery technology. By addressing key challenges related to cost, safety, and performance, this breakthrough paves the way for a new era of innovation in energy storage and reinforces the position of solid-state batteries as a game-changing technology for a sustainable future.

Safer, Cheaper, Lithium Sulfide, Solid-State Batteries, Breakthrough Process, Energy Storage, Electric Vehicles, Renewable Energy, Sustainability, Innovation, Decarbonization.