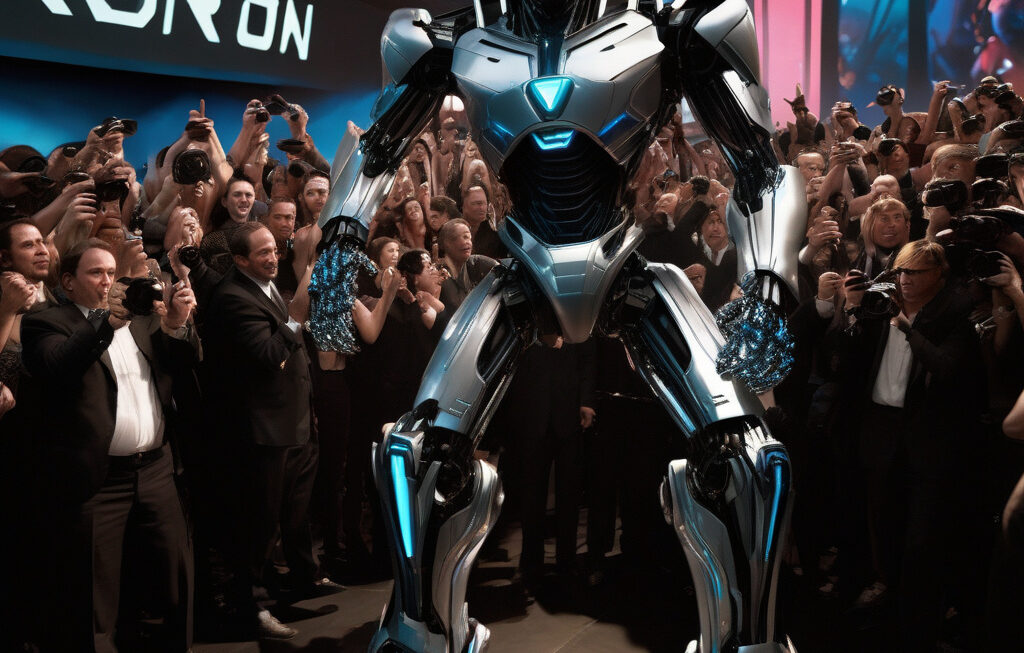

German Humanoid Robot Welder to Tackle High-Risk Jobs at Hyundai’s Shipyard

A partnership will result in Korean firms HD Hyundai Robotics and HD Hyundai Samho testing a cutting-edge solution for high-risk tasks in shipbuilding – a German humanoid robot welder. This innovative collaboration aims to revolutionize the shipbuilding industry by incorporating advanced robotics technology into traditionally labor-intensive and hazardous processes.

The introduction of the German humanoid robot welder marks a significant milestone in the evolution of automation in the manufacturing sector. By leveraging the expertise of German engineering and the precision of humanoid robotics, Hyundai’s shipyard is poised to enhance efficiency, safety, and quality in its operations.

One of the key advantages of deploying a humanoid robot welder is its ability to perform intricate welding tasks with a level of precision that surpasses human capabilities. This not only ensures superior weld quality but also reduces the margin of error, resulting in fewer defects and rework. As a result, Hyundai can expect a boost in productivity and cost savings while maintaining the highest standards of workmanship.

Moreover, the use of a humanoid robot welder addresses the issue of safety in high-risk welding environments. Shipbuilding is inherently hazardous, with workers exposed to various risks such as fumes, heat, and heavy machinery. By entrusting welding tasks to a robot, human workers can be redeployed to safer and more value-added roles, thereby minimizing the potential for workplace accidents and injuries.

Furthermore, the integration of robotics technology aligns with Hyundai’s commitment to sustainability and innovation. As the global push for eco-friendly practices gains momentum, companies are under increasing pressure to reduce their carbon footprint and embrace sustainable solutions. By incorporating a humanoid robot welder into its operations, Hyundai demonstrates its dedication to environmental responsibility and technological advancement.

The successful implementation of the German humanoid robot welder at Hyundai’s shipyard has the potential to set a new standard for automation in the shipbuilding industry. As other companies observe the benefits of this cutting-edge technology, they may be inspired to explore similar collaborations and investments in robotics to drive operational excellence and competitiveness.

In conclusion, the partnership between Korean firms HD Hyundai Robotics and HD Hyundai Samho to test a German humanoid robot welder represents a forward-thinking approach to addressing the challenges of high-risk jobs in shipbuilding. By harnessing the power of robotics technology, Hyundai is poised to enhance efficiency, safety, and quality in its operations, setting a new benchmark for innovation in the industry.

robotics, automation, shipbuilding, innovation, Hyundai’sShipyard