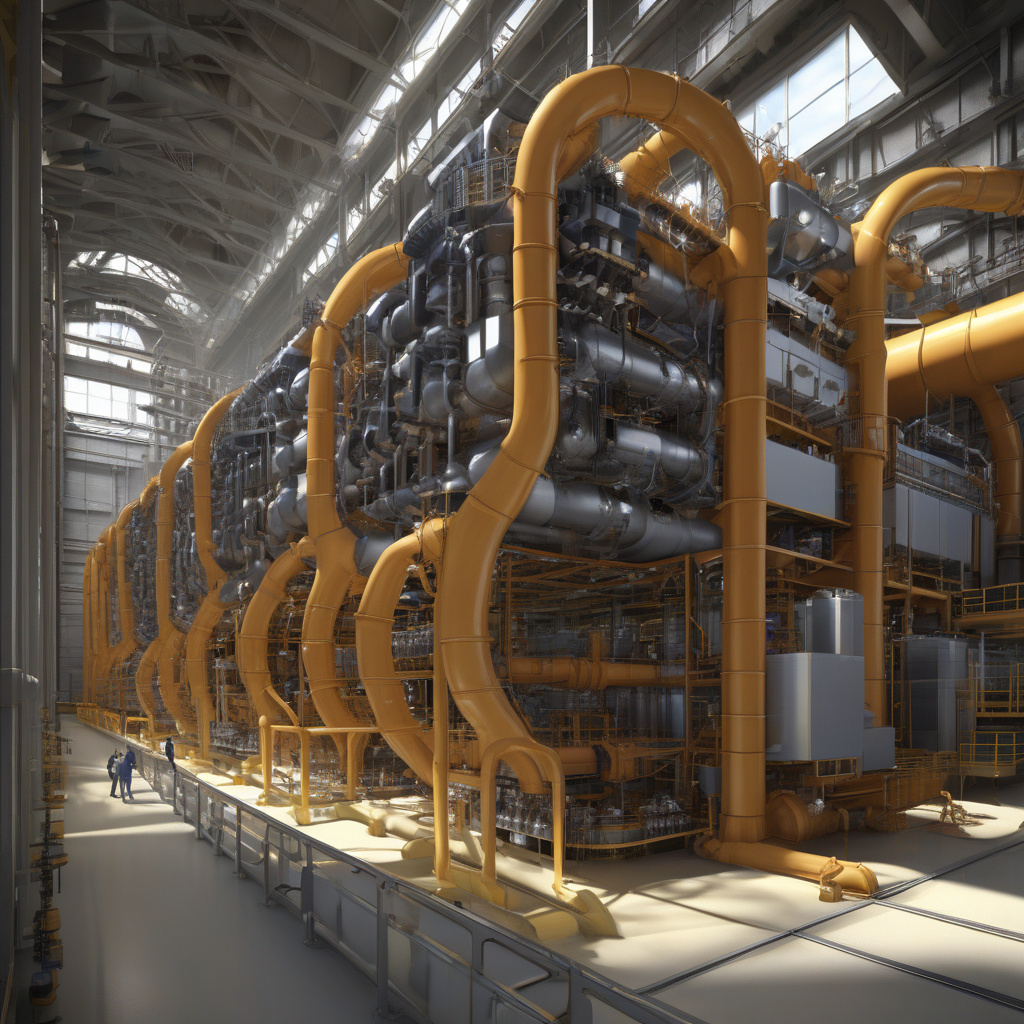

Largest US-built 35 MW PEM electrolyzer deployed at hydro-powered plant in Niagara Falls

A leading company in large-scale hydrogen production has delivered a powerful electrolyzer system that will revolutionize the renewable energy sector. The largest US-built 35 MW PEM (Proton Exchange Membrane) electrolyzer has been successfully deployed at a hydro-powered plant located in the majestic Niagara Falls region. This groundbreaking achievement marks a significant milestone in the journey towards sustainable energy production and underscores the pivotal role of hydrogen technology in driving the transition to a greener future.

The deployment of this massive PEM electrolyzer at the hydro-powered plant is a testament to the increasing demand for clean energy solutions that can meet the challenges of climate change. By harnessing the power of renewable sources such as hydroelectricity, the electrolyzer can efficiently produce large quantities of hydrogen without generating harmful emissions. This not only reduces the carbon footprint of the plant but also paves the way for a more sustainable energy infrastructure.

The PEM electrolyzer operates by splitting water molecules into hydrogen and oxygen using an electrolysis process. The hydrogen produced can then be stored or utilized as a clean fuel source for various applications, including transportation, industrial processes, and power generation. With a capacity of 35 MW, this electrolyzer stands as the largest of its kind in the United States, showcasing the immense potential of hydrogen technology to scale up and meet the growing demand for renewable energy solutions.

One of the key advantages of PEM electrolysis is its flexibility and efficiency in producing high-purity hydrogen with minimal environmental impact. Unlike traditional methods of hydrogen production that rely on fossil fuels, PEM electrolysis enables the generation of hydrogen using electricity from renewable sources, making it a key enabler of the green hydrogen economy. This aligns perfectly with the global shift towards decarbonization and the transition to a low-carbon energy system.

The strategic location of the hydro-powered plant in Niagara Falls further enhances the sustainability credentials of the PEM electrolyzer deployment. By leveraging the abundant hydroelectric resources in the region, the plant can ensure a constant and reliable source of clean energy to power the electrolysis process. This synergy between renewable generation and hydrogen production exemplifies the synergy between different clean energy technologies to drive innovation and sustainability.

Furthermore, the successful deployment of the largest US-built 35 MW PEM electrolyzer sets a precedent for future projects seeking to scale up hydrogen production capacity. As the demand for clean hydrogen continues to rise across industries such as transportation, manufacturing, and energy storage, the need for large-scale electrolysis systems will become increasingly vital. The Niagara Falls project serves as a model for integrating cutting-edge technology with renewable energy sources to meet this growing demand effectively.

In conclusion, the deployment of the largest US-built 35 MW PEM electrolyzer at the hydro-powered plant in Niagara Falls represents a significant milestone in the advancement of sustainable energy solutions. By harnessing the power of renewable hydroelectricity to produce clean hydrogen on a massive scale, the project exemplifies the potential of hydrogen technology to drive the transition towards a carbon-neutral future. As more initiatives like this emerge, the vision of a greener, more sustainable energy landscape grows closer to reality.

hydrogen, PEM electrolyzer, renewable energy, sustainability, Niagara Falls