3D-Printed Superconductor Smashes Record with Unprecedented 50 Tesla Strength

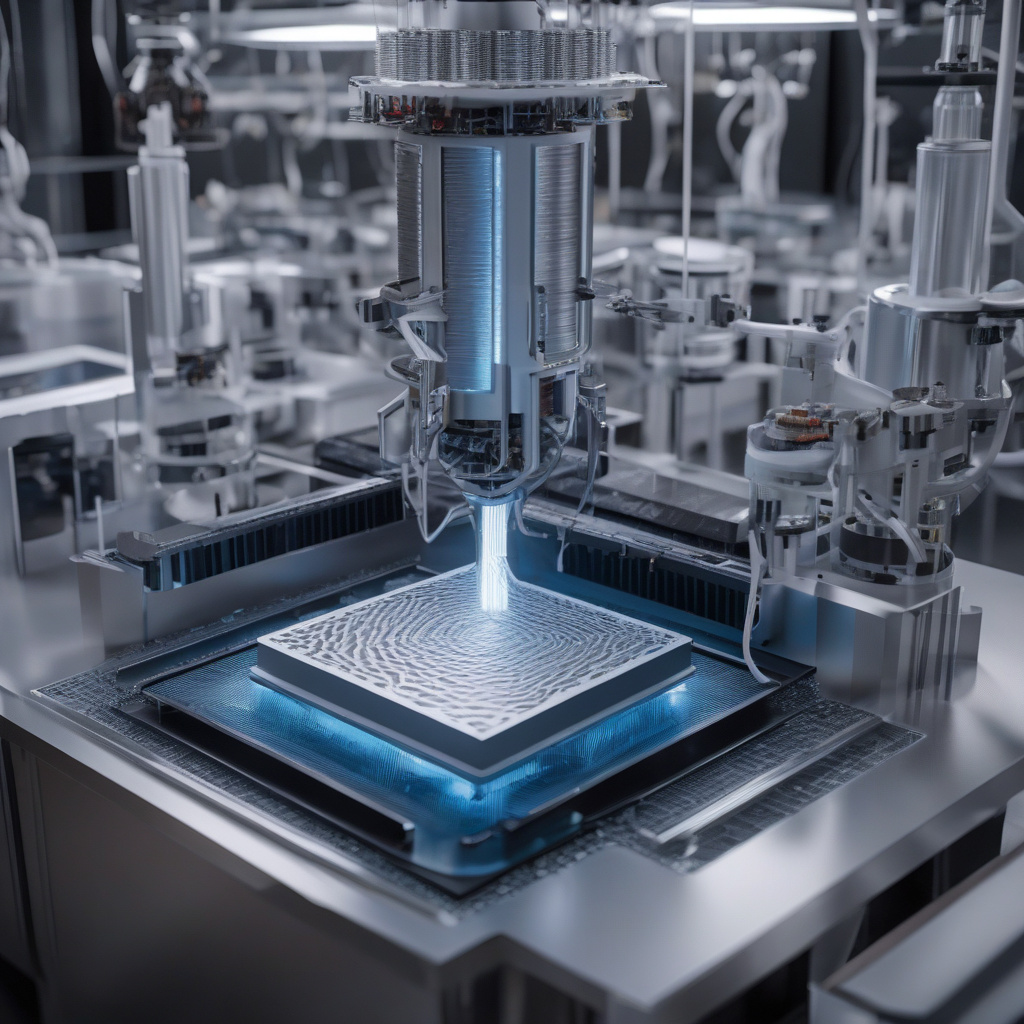

Cornell researchers have developed a one-step 3D printing method to produce superconductors with unprecedented performance. The team’s groundbreaking work has resulted in a superconductor capable of withstanding an impressive 50 Tesla magnetic field, shattering previous records in the field.

Superconductors are materials that can conduct electricity without any resistance when cooled to extremely low temperatures. This property opens up a myriad of possibilities for various applications, ranging from magnetic resonance imaging (MRI) machines and particle accelerators to more efficient power grids and advanced quantum computers.

Traditionally, superconductors have been challenging to produce and manipulate due to the complex processes involved in their fabrication. However, the Cornell researchers have overcome these limitations by leveraging the power of 3D printing technology. This innovative approach not only streamlines the production process but also allows for the precise customization of superconductors with exceptional performance characteristics.

The key to the team’s success lies in the unique composition of the 3D-printed superconductor. By carefully controlling the arrangement of atoms within the material, the researchers were able to enhance its superconducting properties significantly. This level of control is unparalleled in conventional manufacturing methods and highlights the transformative potential of 3D printing in the field of superconductivity.

One of the most remarkable aspects of the Cornell team’s superconductor is its ability to withstand magnetic fields as strong as 50 Tesla. To put this into perspective, conventional superconductors typically fail at much lower magnetic field strengths, limiting their practical applications in high-energy physics and other demanding fields. With this new breakthrough, researchers and engineers now have access to a superconductor that pushes the boundaries of what was previously thought possible.

The implications of this achievement are far-reaching. The enhanced performance of the 3D-printed superconductor opens up exciting new possibilities for the development of advanced technologies that rely on superconductivity. From more powerful MRI machines for medical diagnostics to next-generation particle accelerators for fundamental research, the potential applications of this technology are vast and promising.

Moreover, the scalability of the 3D printing process means that these high-performance superconductors could soon be produced on a commercial scale, paving the way for widespread adoption across industries. This mass production capability has the potential to revolutionize sectors such as energy, healthcare, and information technology, where superconductors play a crucial role in enabling cutting-edge innovations.

As we look to the future, it is clear that the intersection of 3D printing and superconductivity holds immense promise for driving technological advancements and pushing the boundaries of what is achievable. The Cornell researchers’ pioneering work serves as a testament to the power of innovation and collaboration in unlocking new possibilities in materials science and engineering.

In conclusion, the development of a 3D-printed superconductor with a record-breaking 50 Tesla strength represents a significant milestone in the field of superconductivity. By harnessing the capabilities of 3D printing technology, researchers have overcome long-standing challenges and opened up a new chapter in the quest for high-performance materials. The impact of this achievement is poised to extend far beyond the laboratory, shaping the future of numerous industries and driving innovation across disciplines.

superconductor, 3D printing, innovation, Cornell researchers, technology