Tracing PFAS Through Electronics Manufacturing

Per- and polyfluoroalkyl substances, commonly known as PFAS, have been extensively used in various industries for decades due to their unique properties such as water and oil resistance, making them ideal for applications in electronics manufacturing. However, the adverse effects of PFAS on human health and the environment have raised significant concerns, leading to the development of detection methods and strategies for their phase-out and life cycle management within the industry.

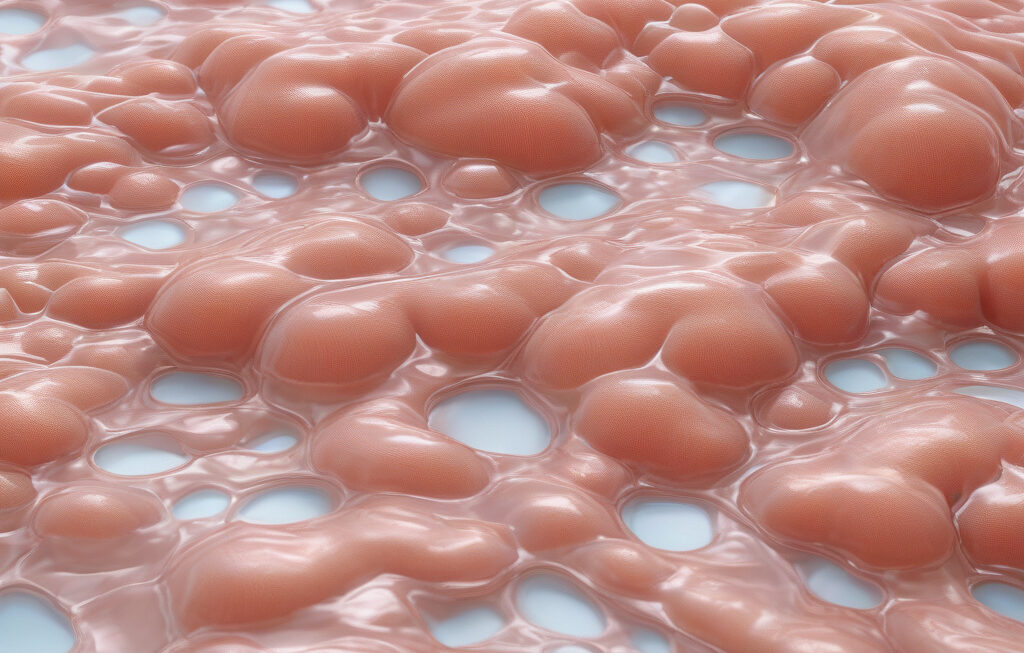

In electronics manufacturing, PFAS are primarily used in the production of semiconductors, printed circuit boards, and other electronic components to impart water and stain-resistant properties. For example, PFAS compounds are often found in the protective coatings of electronic devices, preventing damage from moisture and other environmental factors. While these properties are beneficial for the performance and longevity of electronic products, the persistence of PFAS in the environment poses a significant risk.

The detection of PFAS in electronic manufacturing processes has become a crucial focus for industry stakeholders and regulatory bodies. Advanced analytical techniques such as liquid chromatography-mass spectrometry (LC-MS) and gas chromatography-mass spectrometry (GC-MS) are commonly employed to identify and quantify PFAS compounds in manufacturing facilities. By implementing these sophisticated detection methods, manufacturers can track the presence of PFAS throughout the production process and assess potential exposure risks to workers and the environment.

In response to growing concerns over the environmental and health impacts of PFAS, electronics manufacturers are increasingly adopting strategies to phase out the use of these substances from their products. Companies are exploring alternative materials and technologies that can provide similar functionalities without the harmful effects of PFAS. For instance, research is underway to develop eco-friendly coatings and surface treatments that offer water and oil resistance without relying on PFAS compounds.

Moreover, life cycle management of PFAS in electronics manufacturing involves not only reducing their use during production but also addressing their disposal and recycling. Proper disposal methods are essential to prevent the release of PFAS into the environment, where they can accumulate in soil and water systems. Recycling programs are being developed to recover PFAS-containing materials from electronic waste and ensure their safe handling and disposal through specialized treatment processes.

By tracing PFAS through electronics manufacturing and implementing detection methods and strategies for phase-out and life cycle management, the industry can mitigate the risks associated with these persistent chemicals and move towards more sustainable practices. Collaborative efforts between manufacturers, researchers, and regulatory agencies are essential to drive innovation and transition towards PFAS-free electronics production.

In conclusion, the journey to eliminate PFAS from electronics manufacturing is a challenging yet necessary endeavor to safeguard human health and the environment. By leveraging advanced detection technologies, exploring alternative materials, and implementing comprehensive life cycle management practices, the industry can pave the way for a cleaner and safer future in electronic production.

The post Tracing PFAS through electronics manufacturing appeared first on Innovation News Network.

electronics manufacturing, PFAS, detection methods, phase-out, life cycle management